INVESTMENTS IN EGYPT ON A ROLL | Saint Gobain

The Ain Sokhna float plant in Egypt will see its capacity increased with the construction of a second flat glass Continue Reading →

admin.glass /April 19, 2024

The Ain Sokhna float plant in Egypt will see its capacity increased with the construction of a second flat glass Continue Reading →

admin.glass /April 12, 2024

Minden – cericom laser has transitioned to become a 100% member of the LiSEC Group. This strategic move underscores LiSEC’s Continue Reading →

admin.glass /April 8, 2024

Şişecam, the sole global player operating in all fundamental areas of glass and pioneering many innovations in the Flat Glass Continue Reading →

admin.glass /April 6, 2024

With less iron content than standard clear glass, Guardian CrystalClear glass brings the barely there look of low-iron glass to Continue Reading →

admin.glass /April 5, 2024

The seventh term of Şişecam’s Global Young Talent Program “Together” has officially commenced. A total of 152 young talents selected Continue Reading →

admin.glass /April 3, 2024

When the markets and industries keep changing, it is good to keep the essentials in mind – trusting the originals Continue Reading →

admin.glass /April 2, 2024

It will supply the modules for Sprng Energy’s upcoming project in Gujarat, Waaree Energies said in a statement Waaree Energies Continue Reading →

admin.glass /April 2, 2024

On March 15th and 16th, 2024, NorthGlass held the managers’ working meeting in Luoyang with the theme of “Working Together, Continue Reading →

admin.glass /April 2, 2024

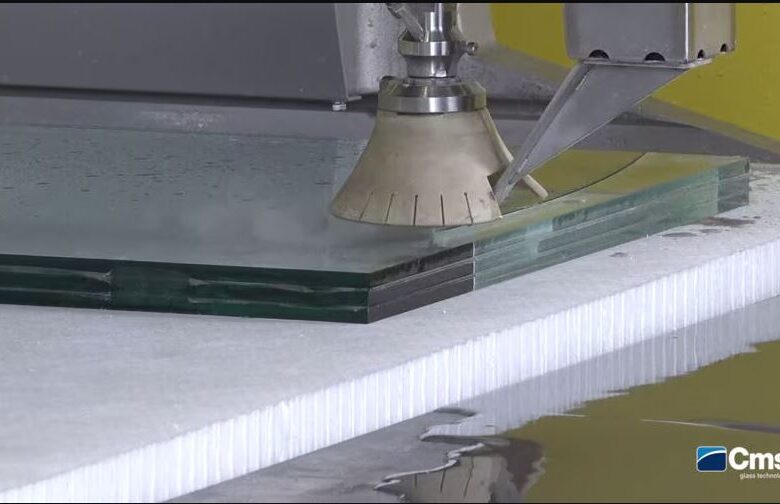

Cutting thick safety glass without compromising on cycle times can be quite a challenge, especially if the glass is thicker than 19mm and Continue Reading →

admin.glass /March 30, 2024

Şişecam has ignited its new glass packaging furnace in Eskişehir and put its glassware furnace into operation after cold repair. Continue Reading →

admin.glass /March 30, 2024

Indosol Solar, by Shirdi Sai Electricals, launching a Centre-approved 10,000 MW Project in Andhra Pradesh. The Facility at Ramayapatnam includes Continue Reading →

admin.glass /March 29, 2024

Shortly before starting production on a new, fully automated warehouse, cutting and IG line in Chaves, Portugal’s no. 1 all-in-one Continue Reading →

Follow Us At: