Eggersdorf bei Graz (Austria) | Austrian based REDWAVE has been developing ground-breaking solutions for the recycling industry for over 25 years. In addition to sorting machines and sorting systems for the extraction of recyclable materials, REDWAVE recently delivered the first fully automatic quality control system in mobile container design to one of the largest glass manufacturers in Germany.

In October 2022, Wiegand-Glas, one of the largest family-owned glass manufacturers in Germany, took possession of REDWAVE’s Qi, the first quality control system engineered to fit into a mobile shipping container. As clean cullet is the most important raw material in glass production, and high-quality cullet is a prerequisite for a strong final product, contaminants such as ceramics, stones or porcelain can instigate massive financial loss in glass production. Additional impurities found in heat-resistant and non-melted glass-ceramic particles can slip into the cullet, leading to weaknesses in the newly produced glass and increasing the probability of shattering. In order avoid these impurities, Wiegand-Glas invested in REDWAVE’s mobile container-housed quality control system: the REDWAVE Qi.

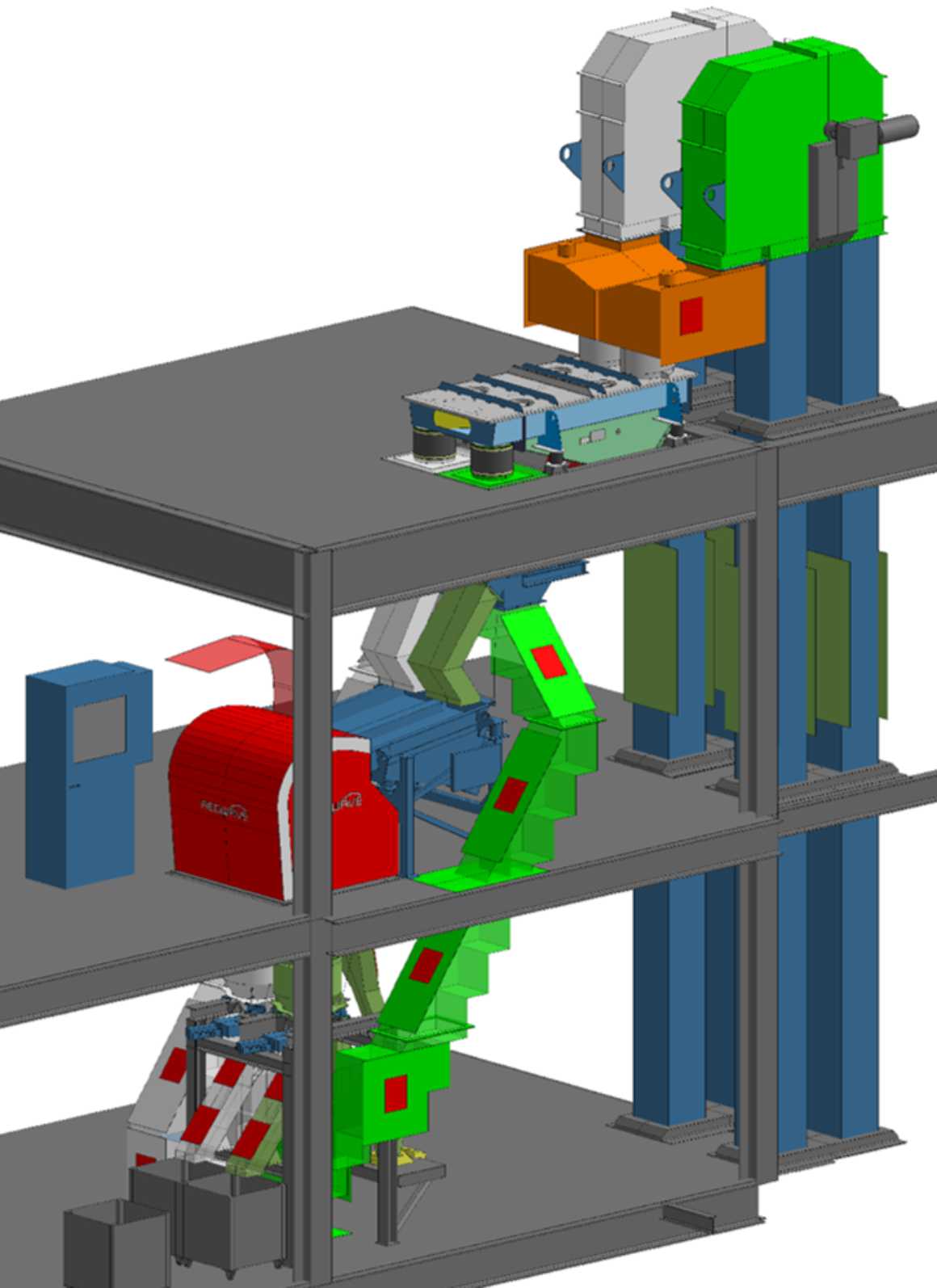

If REDWAVE Qi is permanently integrated in a sorting system, quality assurance and quality control are already carried out during the sorting process. In the mobile shipping container variant, a pre-determined, unscreened sample is transported via a conveyor belt into the machine for analyzation. The sample is examined, and the impurities are ejected for further analysis. The material, as well as the ejected impurities, are weighed in order to determine the contaminant content and then re-evaluated.

REDWAVE Qi can be designed as a mobile container solution, stationary integrated into a plant or, as a single analysis system.

As a stand-alone, mobile container solution or integrated into an existing sorting plant, the system is increasingly used in glass recycling or in glass production for quality control. The analysis evaluations serve as proof of the quality of the cullet.

The container is pre-assembled mechanically, electrically and pneumatically, at REDWAVE’s warehouse, which eliminates cost-intensive on-site assembly times for the customer. If the conditions at the existing location change or if the container is needed in another system, it can be easily moved and quickly installed elsewhere.

An input material sample is continuously taken from the product stream, during the ongoing sorting process, to ensure the quality of the final product. The sample quantity is controlled by the setting of the opening time, and opening frequency of the flap, and can be up to 10% of the total input. An additional advantage of quality control is that the continuous analysis and control of the material makes troubleshooting in a sorting system much easier (e.g. for the screen mats or the sorting machines). Stationary integration ensures the full functionality of the system and targeted data evaluation makes it possible to increase plant efficiency.

About REDWAVE:

REDWAVE has been developing solutions for the recycling industry for over 25 and is a leading manufacturer of sensor-based sorting machines and entire sorting systems for the recovery and sorting of recyclable materials. REDWAVE operates worldwide and, in addition to its headquarters in Austria, has further branches in Germany, China, Singapore and the USA.

Questions and contact:

Mag. (FH) Angela Thaller, Marketing & PR

Tel. +43 664 80155 2276

E-Mail: angela.thaller@redwave.com

REDWAVE, a division of BT-Wolfgang Binder GmbH

Wolfgang Binder GmbH 4, 8200 Eggersdorf near Graz, Austria

Webpage | LinkedIn | Youtube