Felbermayer Confident Full Automation, Output And Actual Costs Give It Massive Advantages

‘LiSEC only manufacturer that can supply everything needed – machinery, software and services. Thanks to its all-in-one solutions, all coordination takes place internally.’

Felbermayer Fenster & Türen was founded as a joinery back in 1964. In 1993, Helmut Felbermayer took over the company from his father. Back then, only two employees worked in the small company in Klosterneuburg/ Lower Austria. Over the years that followed, Mr Felbermayer has gradually expanded the company. Today, 210 employees work at the site in Unterwaltersdorf, Lower Austria, on the production of windows and doors, insulating glass manufacturing and powder coating. Felbermayer works together with subcontractors on installations.

Felbermayer Fenster & Türen Erzeugungs GmbH, which produces the windows and then sells them to Felbermayer Vertriebs GmbH, which in turn takes care of the installation.

The company is primarily active in the contract market and it covers the market from Vienna and Graz to Salzburg and Vorarlberg – supplying windows made of wood, woodaluminium, plastic and plasticaluminium.

In 2021, Felbermayer generated sales of 44.2 million euros, while the figure this year is expected to stand at 50 million euros. “We have developed the window such that highly automated finishing is possible. That’s our strength compared to the competition. We achieve a high output with a very small number of employees,” Managing Director Helmut Felbermayer said.

Previously, Mr Felbermayer always bought in the insulating glass.

He said, “I always purchased exclusively from Interpane. Then the company’s managing director, Mr Hattmannsdorfer, recommended that we manufacture the insulating glass ourselves because the required quantities and scale were suitable for in-house production. Initially, I literally laughed at him. However, one time while away on holiday I mentally went over the scenario and relatively quickly came to the conclusion that it wasn’t such a bad idea at all.”

“Over a period of two months, plans were sent back and forth almost daily to identify the best possible solution – and I think we succeeded. The collaboration worked really well. It was a joint project that was also thoroughly enjoyable,” said Mr Felbermayer. And he is delighted with the project progress to date: “Top performance was delivered by everyone involved.

The excavator arrived at the end of February/beginning of March 2021. In August, the hall was ready on schedule and installation of the machinery began. This continued in stages at full throttle, right up to the start of production. We had an outstanding team from LiSEC!” Mr Felbermayer went on to report that everything on the project worked, from the machines to the software, and no mistakes were made: “We would do everything exactly the same again. Throughout my career – during which we have bought numerous machines and planned plants – I have never experienced such perfect implementation within such a timeframe.”

Felbermayer is the only contract window company that manufactures the insulating glass itself. Mr Felbermayer is confident that “thanks to the full automation, output and the actual costs, we enjoy massive advantages over the competition”.

LiSEC’s solutions satisfy Mr Felbermayer’s expectations. He has always known the LiSEC name: “I have always had an eye on insulating glass production – we are genuine machine freaks at heart. We’ve been attending trade fairs for years and we have seen LiSEC machines and the machines offered by competitors. It has been clear to us that LiSEC tops the list when it comes to machinery construction.”

The software is also impressive: “Machines are one thing, but the software behind them makes a big difference too. The installation went without a hitch – we had nothing to worry about. Our LiSEC software contact worked together with my colleague Gerhard Czervenka to compile all the basic data and update the master data and the whole thing was up and running.”

Mr Felbermayer highlighted the advantages of obtaining solutions from a single source: “With the project being highly complex in nature, it was hugely beneficial to work with LiSEC – because everything came from a single source. LiSEC is actually the only machine manufacturer that can supply all the elements you need: Machinery, software and services. Thanks to the all-in-one solutions at LiSEC, all coordination takes place internally and you don’t really notice (or only rarely notice) the coordination and planning measures that are taking place in the background – yet another huge advantage with LiSEC: they make it look easy!”

It was not only the range of machines and software that impressed Mr Felbermayer: “I believe that the machinery construction is more carefully thought-out than in other companies. The development phase takes longer than that of the competition. It is clearly apparent in the workmanship and components that everything is very coherent. The LiSEC design department does an excellent job.”

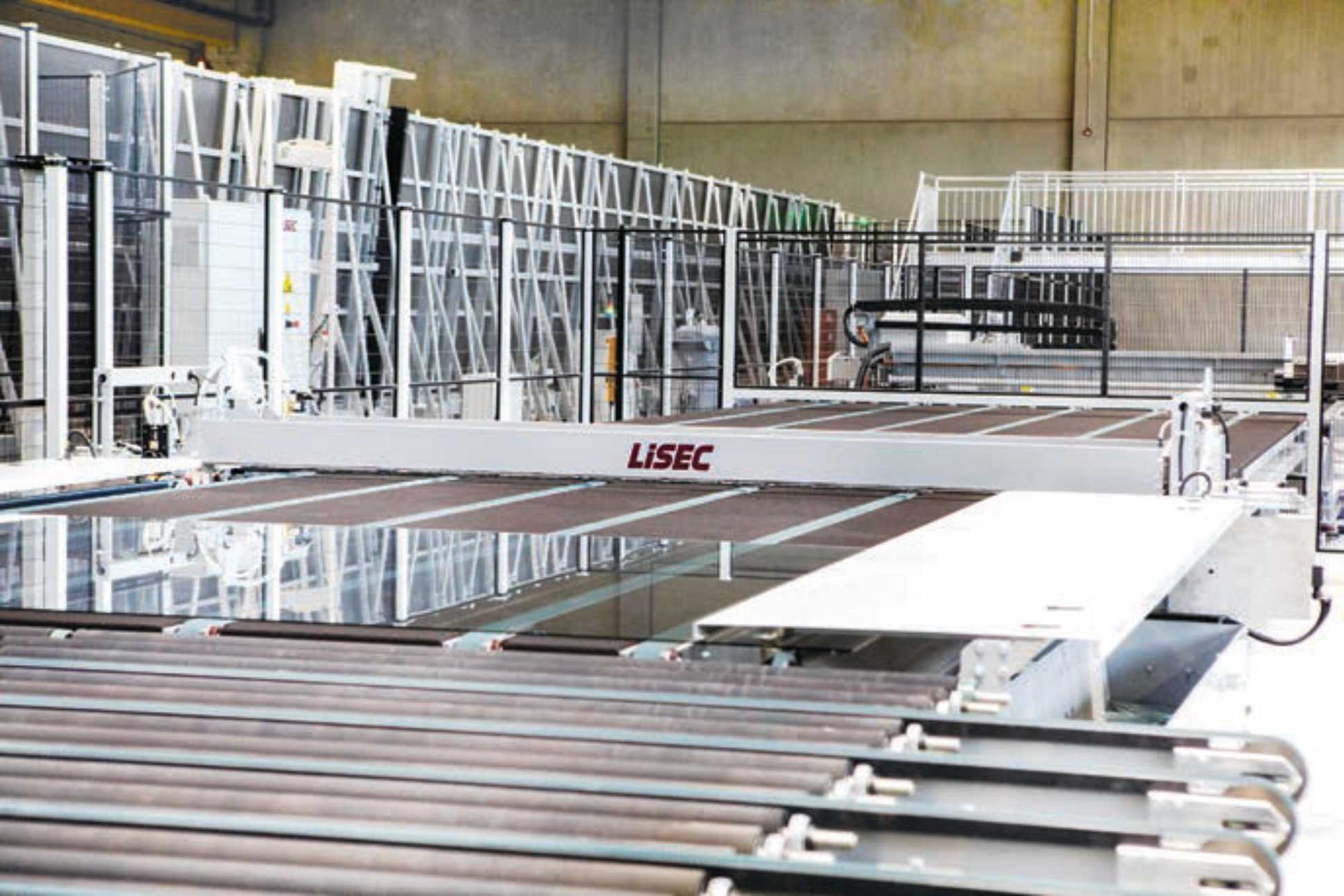

The LiSEC machinery fleet at Felbermayer includes the following

machines: PKL/SBL, ESL-RS, two VSL-A stations, KSR, GSL, VHW-F, ARL, TPA-A, AGP-A, VFL-1F as well as automatic tempering bed loading and unloading. The glass is loaded by the PKL/SBL glass gantry loading system. With its rotating double suction frame, the system is able to stack large format sheets automatically and precisely.

In addition to cutting flat glass using the LiSEC ESL-RS cutting table, Felbermayer has two LiSEC VSL-A cutting systems with Dynamic Load Balancing for cutting laminated glass. This is an intelligent form of dynamic utilisation control that can achieve a high output. The edges are seamed with the LiSEC KSR processing machine.

Once the quality has been checked by the GSL quality scanner, the sheets are sorted into the ASM sorting magazine by the SHL glass transport shuttle. The system is able to pick up glass lites sheets vertically and horizontally, buffer and transfer the sheets, and transport them between the processing stations.

The VHW-F is characterised by features including its flexible expandability, the contactless spindle guide and the self-cleaning gap filter system in the washing zone area. The sheets are washed and dried in an energy-efficient manner and with optimum polishing quality. With the desiccant filling machine ARL-45F, spacer frames made from all common materials can be filled with desiccant, both as rectangular frames and as shapes.

Filling at the back of the frame guarantees a stable process, even with delicate plastic materials.

The optional measurement of the desiccant quantity can ensure that there is sufficient desiccant in the frame compared to other systems.

The LiSEC TPA – a fully automatic system for applying thermoplastic spacers – enables maximum flexibility by seamlessly changing between the different dimensions of the glass.

The stepless width adjustment allows switching between different spacer widths without the requirement for a waiting time.

The high-end gas filling press AGP-A is suitable for a wide range of applications due to the individual configuration options and impresses with the highest precision and quality.

The LiSEC VFL-1F is a system for sealing insulating glass units with two component sealants. The perfected build-up of this system guarantees a high degree of process reliability and top corner quality – even for units with a high weight.

The economy has changed dramatically since 2020. “We are currently experiencing an economic situation that we have never had before. The damage is not even fully tangible yet. The coming years will be difficult for every company,” said Mr Felbermayer.

He is delighted to have accelerated the insulating glass production project: “The insulating glass and the financial savings it delivers benefit us because we have a huge advantage over the competition, thanks to production automation. It was the right decision for us to bring this forward. It will be a big help to us in the long run and with the challenges of the coming years.”

About the company

LiSEC, headquartered in Seitenstetten/Amstetten, is a globally active group that has provided individual and comprehensive solutions in flat glass processing and finishing for 60 years.

Claudia GUSCHLBAUER

Email: claudia.guschlbauer@lisec.com

Website: www.lisec.com