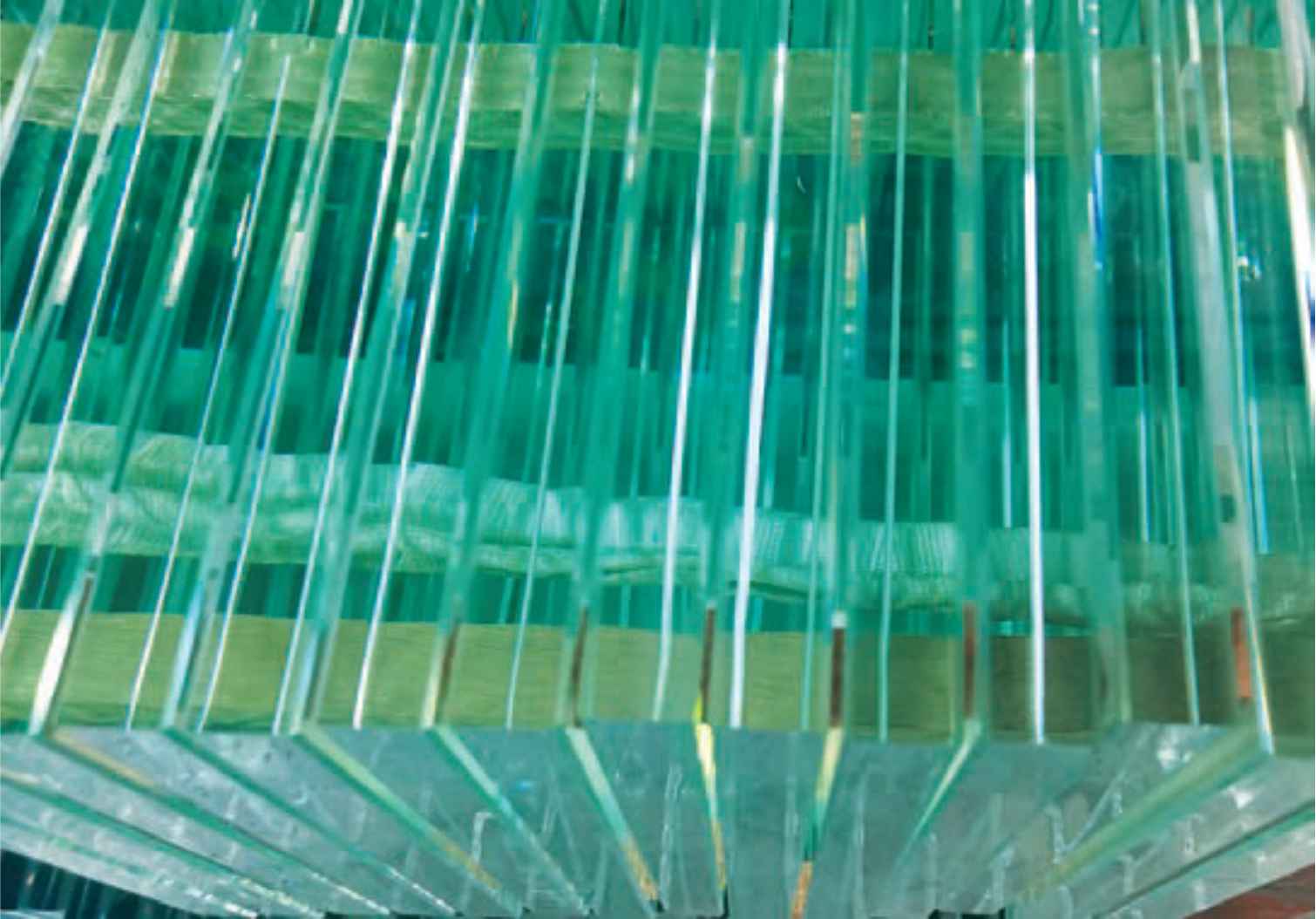

Brings 16m Supersize Glass Double Edging Machine With 30 Spindles, Full Servo Control & Low-E Film Removing Function

Includes intelligent detection and L-shape transfer tables which ensure processing accuracy, high-speed opening and closing speed o f the machine is stable a t 25m/min.

In modern society, with the desire for architectural aesthetics becoming higher and higher, people are no longer satisfied with traditional bricks, tiles and normal glass-sized buildings.

Architectural curtain walls are gradually being recognized and used by more and more builders, and this is a growing trend. Supersized glass curtain walls have come into being at the proper time, and are becoming more and more popular in construction projects.

The company had the foresight of supersize curtain wall glass building projects, and it stemmed from the fact that precision and efficiency of end-grinding processing could not be guaranteed because of the speed and inconvenience of supersize CNC working centers.

The company has created the first super large double edging machine with 30 motors, full servo control and film deletion function. It includes an intelligent detection table and L-shape transfer table which not only ensures processing accuracy, but also the high-speed opening and closing speed of the machine is stable at 25m/min. The maximum edging speed is 25m/min. These data have already occupied the leading position in the field of glass double edging, also breaking the traditional edging technology.

After the double edger ran for production, the customer lauded the company for the technical capability and the processing accuracy of the machine. When the maximum glass size is 3300x16000mm with the glass thickness 10-19mm, the glass finally reaches dimensional accuracy±0.5㎜, diagonal accuracy can be±0.5㎜/m.

The super large size, processing precision and perfect polishing quality of the product are all pioneers in the glass pre-processing field.

When every customer was still troubled by the continuous adjustment of more than 20 spindles grinding amount every day, LIFENG began to provide automatic edge grinding machines to some top glass deep-processing customers in 2016.

LIFENG’s fully automatic intelligent double edging machines have been provided to more than 30 intelligent factories across the country. By connecting ERP and MES systems, without any labor adjustment and just through LIFENG’s automatic comparison system, the intelligent proportioning of grinding amount, automatic grinding wheel compensation technology, the company has changed edging from the dirtiest and most manpower intensive process to a clean, exquisite, and accurate product processing procedure.

All the good results are not accidental. LIFENG began to invest in high-speed intelligent edging machines in 2010. In the few years before the market upgrade, LIFENG continued to invest in research and development and waited for the market to bloom.

In the past 5 years, the company has become the number 1 brand in edging technology. Its factory area has grown from 5,000m2 in 2016 to 50,000m2. Now the monthly production capacity reaches 30 pcs double edging lines.

LIFENG is looking forward to more cooperation and discussions with global glass deep-processing enterprises to help them upgrade the quality and quantity of glass processing.

Ms. Claire Ho

Email: export@lifeng-machinery.com

Website: www.lifeng-machinery.com