Shortly before starting production on a new, fully automated warehouse, cutting and IG line in Chaves, Portugal’s no. 1 all-in-one flat glass supplier VITROCHAVES talks about customer-orientation, the importance of reliable solutions, and 40 years of growing together with LiSEC.

FROM SMALL BEGINNINGS TO MAJOR PLAYER

VITROCHAVES was founded in 1980 by the brothers Chaves Alves on a 50 sqm area in the town centre of Chaves (no relation) in northern Portugal. Within 40 years, continuous investment in innovative solutions has allowed VITROCHAVES to grow into a market leader with three production centres in Chaves, Benavente, and Felgueiras with a total of 26,000 sqm and approx. 200 employees.

MARKET LEADERSHIP AS ALL-AROUND SUPPLIER

“As a versatile company, we are adaptive to market demands and offer an ever-growing range of products,” says Joaquim Chaves, co-founder, and administrator of VITROCHAVES. “Our products become unique through the fusion of our brand and quality. Currently, we supply a diverse range of products from the ISOLAR® glass line that have consistently earned us recognition for over two decades.” ISOLAR® is a European association of manufacturers specializing in highly efficient insulating glass for windows and facades.

Sustainability is another important factor, as Mr. Chaves explains, “Beyond the fundamental respect for the environment, we have adopted practices that actively contribute to our societal responsibilities. Examples of these initiatives are the recycling of all glass and other solid waste, such as wood and plastic, implementing water treatment processes and adopting a systematic approach to reuse valuable resources.”

RELIABLE MACHINERY AND SOFTWARE SOLUTIONS FOR HIGH QUALITY OUTPUT

“We pride ourselves on using the best equipment possible,” Mr. Chaves succinctly sums up the company’s investment strategy. “The initial interaction with LiSEC was the result of thorough research and exploration within the industry. LiSEC’s solutions align with our goals and allow us to achieve superior production times, enhancing our organizational efficiency and contributing significantly to our long-term success.”

The first machine VITROCHAVES bought from LiSEC was a double-glazing line for 3500 x 2000 mm glass, one of the largest machines manufactured at the time. Affectionately called “dinosaur”, the 1993 line is still in operation today. “Our goal has always been reliability and long-lasting performance,” so Mr. Chaves.

“LiSEC has proven to be exceptionally reliable over the years. The enduring performance of their equipment shows their commitment to providing robust and dependable solutions.”

In 2001, another IG line followed – again a top-of-the market solution at the time. Mr. Chaves comments: “LiSEC’s competence is evident thought the longstanding and successful history of collaboration with our company. Their proficiency in delivering quality products and services has consistently met and exceeded our expectations.”

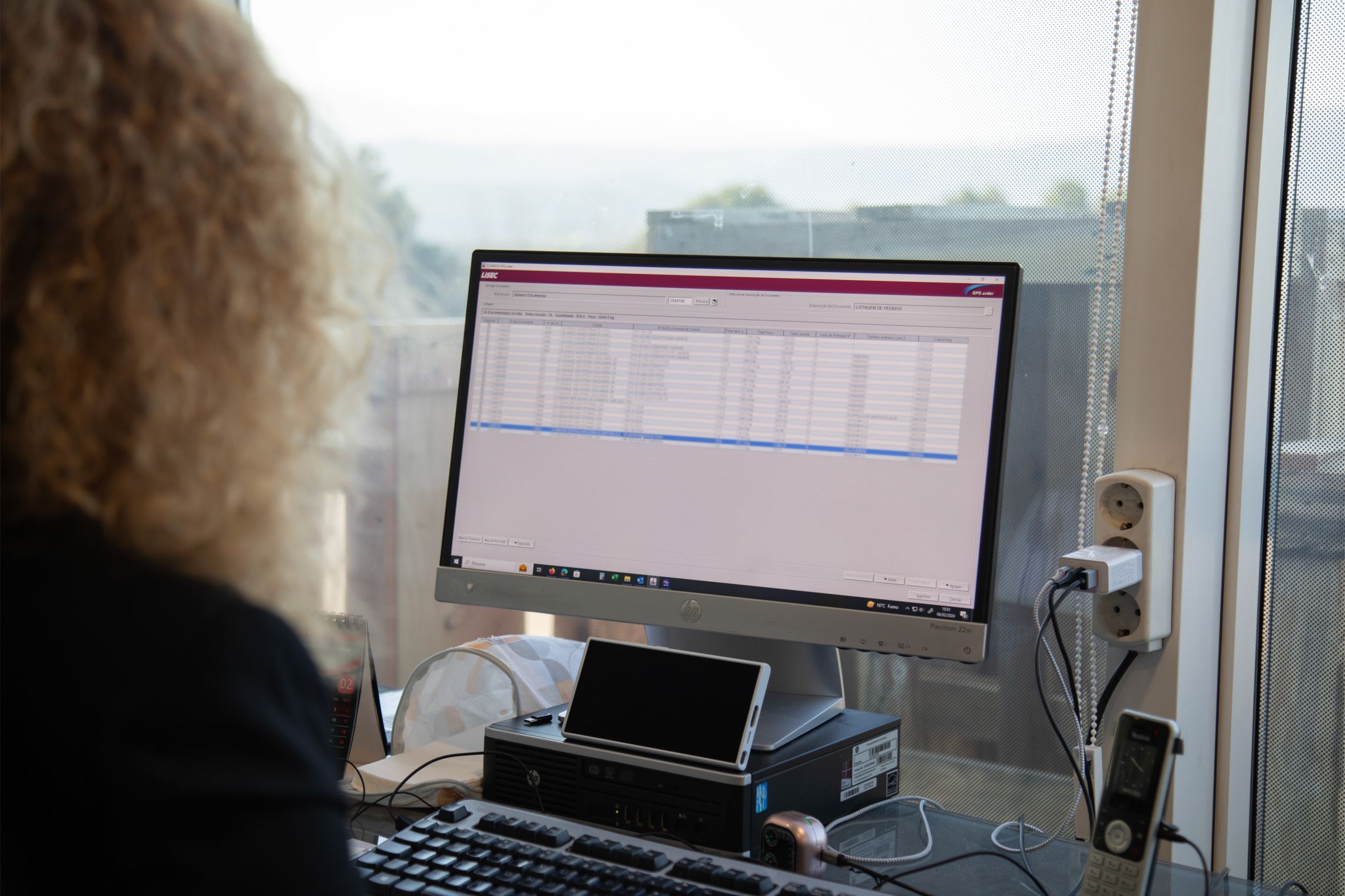

Perfectly in tune with the machines, VITROCHAVES also uses LiSEC software solutions, at the shopfloor as well as in the office. The GPS.prod cutting optimization is server-based and can be run simultaneously by multiple users, an important feature to decrease the amount of time needed in the production planning office. The system allows running multi-optimizations in parallel within the same production batch at the same time, e.g. float glass and low-e. All production information can be shown graphically in detail on monitors on the shop floor. Scanning the barcode from a label, production list or from print on the glass brings up the drawing on the monitor providing all technical details to the operator.

“Without a doubt, the standout features of the LiSEC products are their unmatched reliability and constant innovation. These qualities have consistently set LiSEC apart, making it our top recommendation for others,” says Mr. Chaves.

MOVING INTO A FULLY AUTOMATED FUTURE: VITROCHAVES’ NEW IG PRODUCTION

“LiSEC stands out as an innovative partner,” Mr. Chaves says. “A prime example of this innovation is being showcased in the ongoing installation at VITROCHAVES – a fully automated factory that spans from the glass warehouse to the double-glazing exit.”

This high degree of automation is made possible by a sorting buffer system, coordinated by the GPS.autofab software solution. GPS.autofab controls the fully automatic supply of data to all machines and the routing of the sheets through the sorting system. This means operators no longer have to enter data at the machines and ideally no longer have to touch the glass between cutting and the IG line. Glass sheets can be traced throughout the production process and the operators and production management are informed about the status of the production and the individual connected systems.

Mr. Chaves on his goals with the new production: “We want to expand our production capacity and take full advantage of automation to reduce costs and labour.”

ENSURING CUSTOMER LOYALTY THROUGH PRODUCT INNOVATION

A major trend VITROCHAVES sees on the market is significant innovations in product development and quality standards. “As these changes have a substantial impact on our profitability, we must adapt through continuous updates to our facilities and equipment. The evolving landscape demands a dynamic response to stay at the forefront of industry expectations, making it imperative for us to invest in cutting-edge technologies and stay aware of emerging trends,” says Mr. Chaves.