Innovative Solutions For Small Glass Manufacturing

Delve into the intricate world of small glass manufacturing, focusing on the precision and innovation offered by Bright Glass Machinery.

We see big glass doors and windows everywhere. Due to the characteristics of glass’s transparency, hightemperature resistance, and wear resistance, more and more products are choosing glass instead of traditional materials, such as wall switches, gas stoves, and refrigerator door panels. Bright Glass Machinery, located in Shunde, Guangdong, China, is a company that produces glass double edging machines specifically and professionally for such small size glass with its precision.

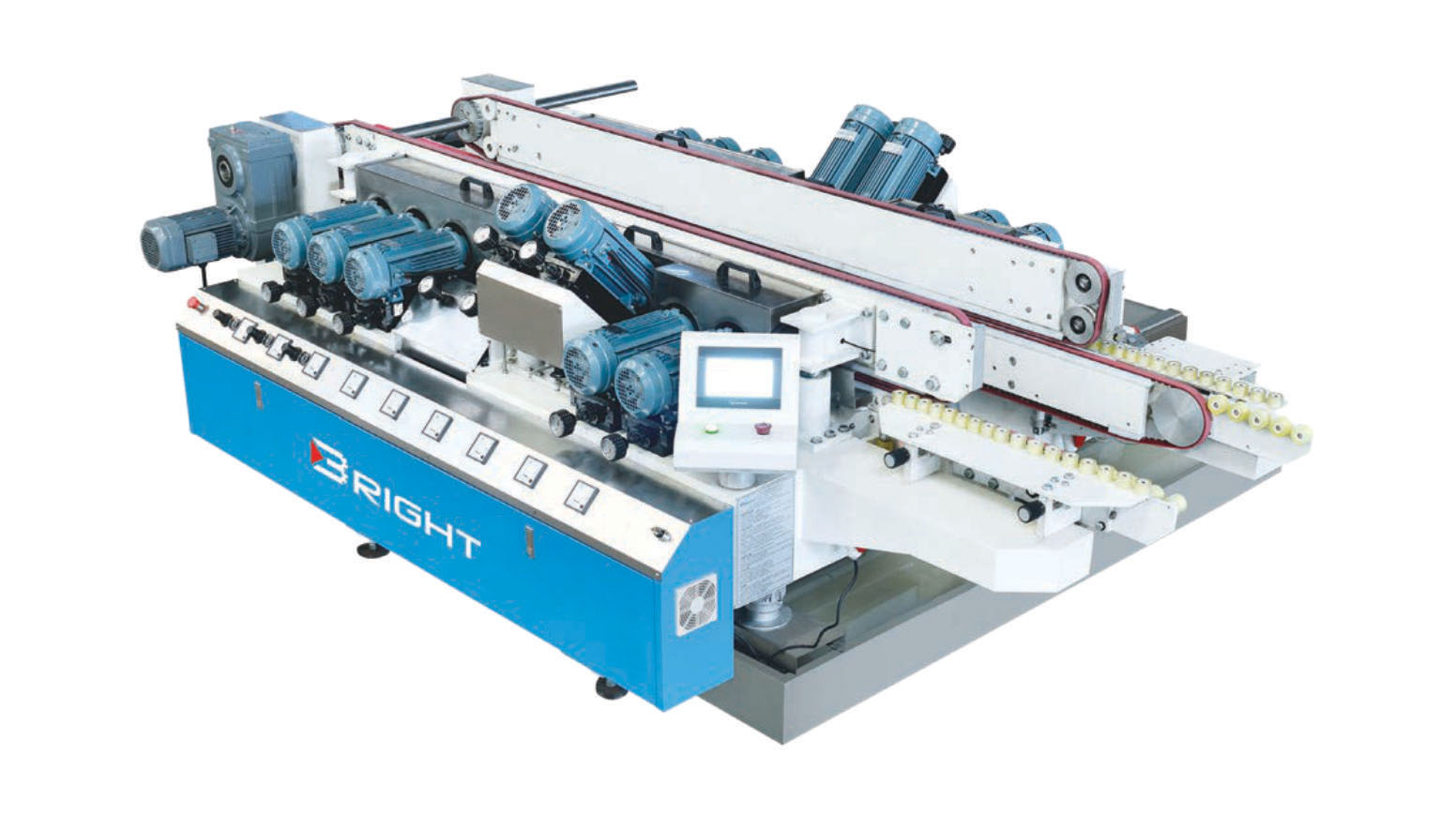

One-time edging passes from bottom grinding, 45° arris grinding to fine polishing. The machines are flexible to design not only the number of spindles but also the grinding wheel configuration according to customer’s needs.

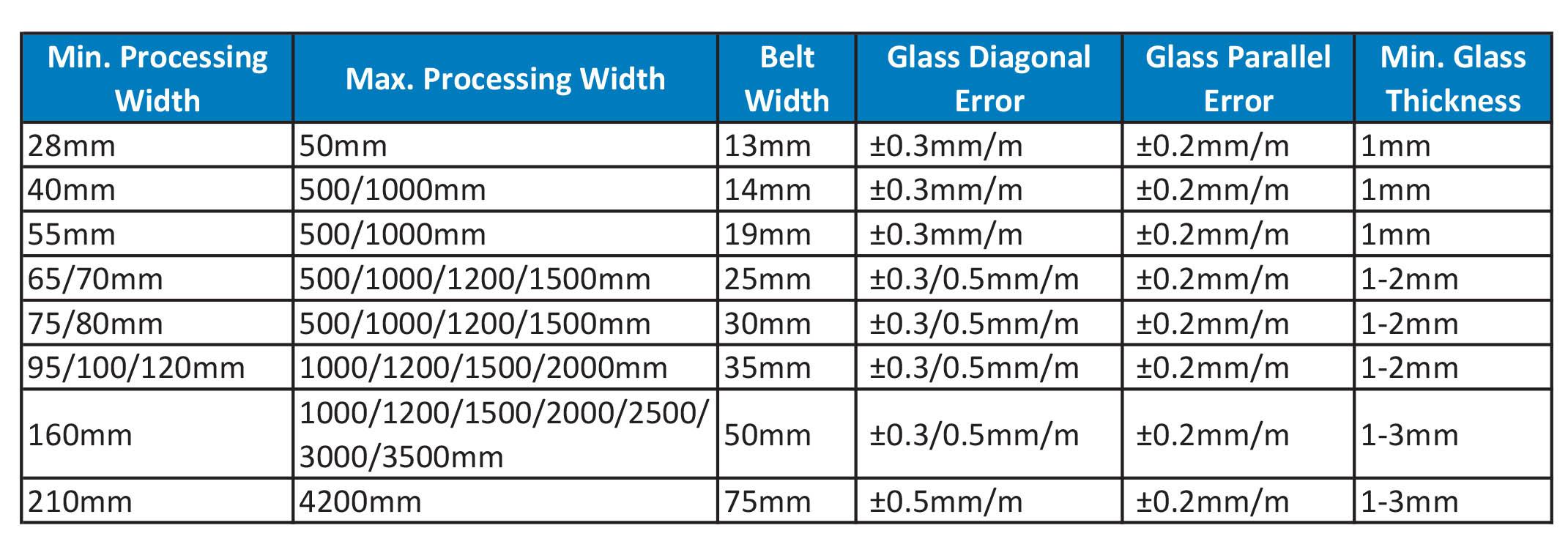

Machine structure looks simple and compact with a small footprint, but with its inside delicate exquisite workmanship, Bright can double edge min.28mm width glass, using different width belt for different small size glass, min.40/55/70/80/100/120mm width are available to be selected.

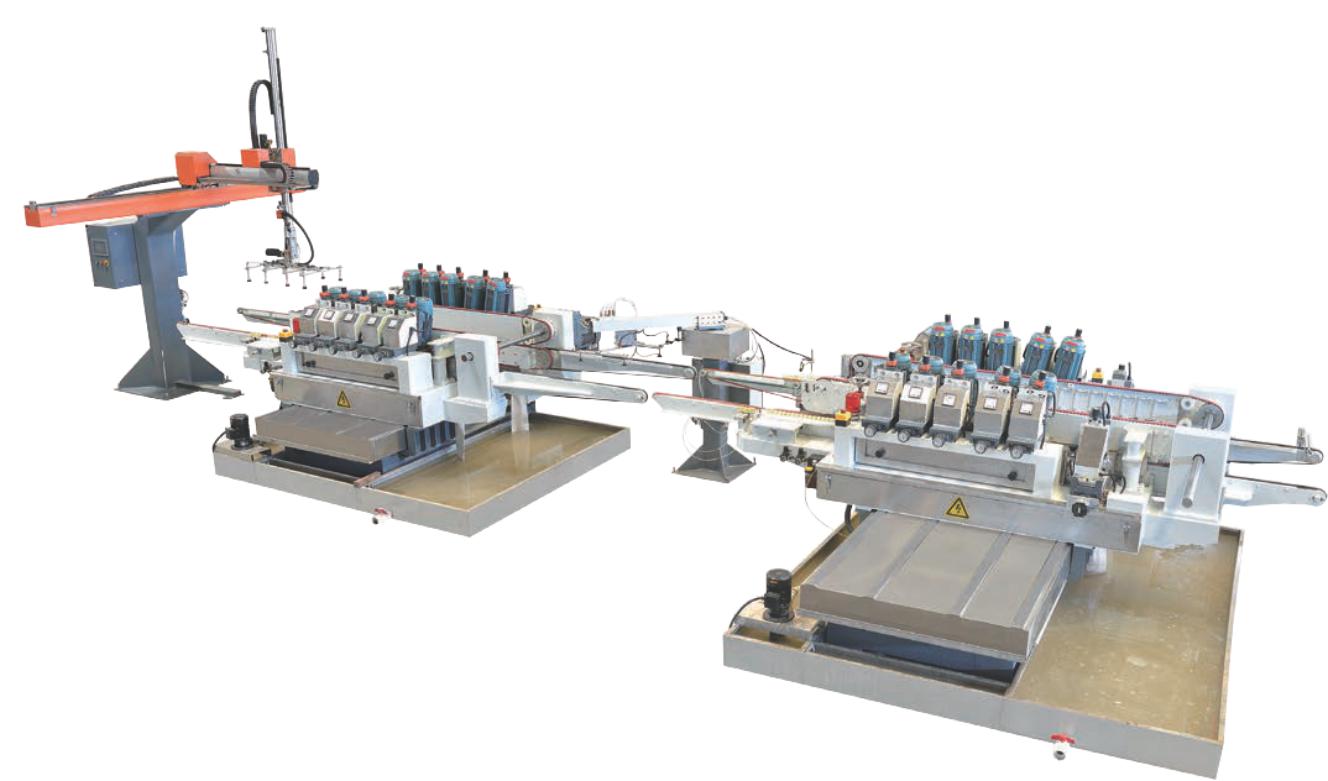

It offers a bigger processing range than a common glass double edging machine. Diagonal error reaches ±0.3mm/m for home appliances glass which has high requirement in precision and polishing. Robot manipulator loading and transferring are adopted to form a production line finishing four sides of glass at a time, improving greatly small glass mass production ability and solves the problem of single side edging machine and CNC non-efficiency.

It offers a bigger processing range than a common glass double edging machine. Diagonal error reaches ±0.3mm/m for home appliances glass which has high requirement in precision and polishing. Robot manipulator loading and transferring are adopted to form a production line finishing four sides of glass at a time, improving greatly small glass mass production ability and solves the problem of single side edging machine and CNC non-efficiency.

Additionally, engraving, safety corner cut and radius corner grinding added makes small glass production diversified and innovative.

Bright small glass double edging machine applies to household glass and electrical glass mainly. Typical sizes are 86x86mm wall switch panel, 464x484mm gas stove. Even arris size, clear and bright polishing, distinct edges and corners, no dim side, no chipping round edge, stable performance, and lower failure rate make us well known in China.

With professional and in-depth knowledge of small glass double edging, Bright offers a suitable solution according to your requirements.

If you feel doubts how small glass double edging can be precise and faster, please look on Bright Side!

Email: export@sdbright.cn

Website: www.sdbright.cn, www.brightglassmachinery.com