Follows 3S Principle: Simple Design, Simple Operation, Simple Maintenance

HISENG’s cutting-edge double edger promises simplicity in design, operation, and maintenance for enhanced glass processing efficiency.

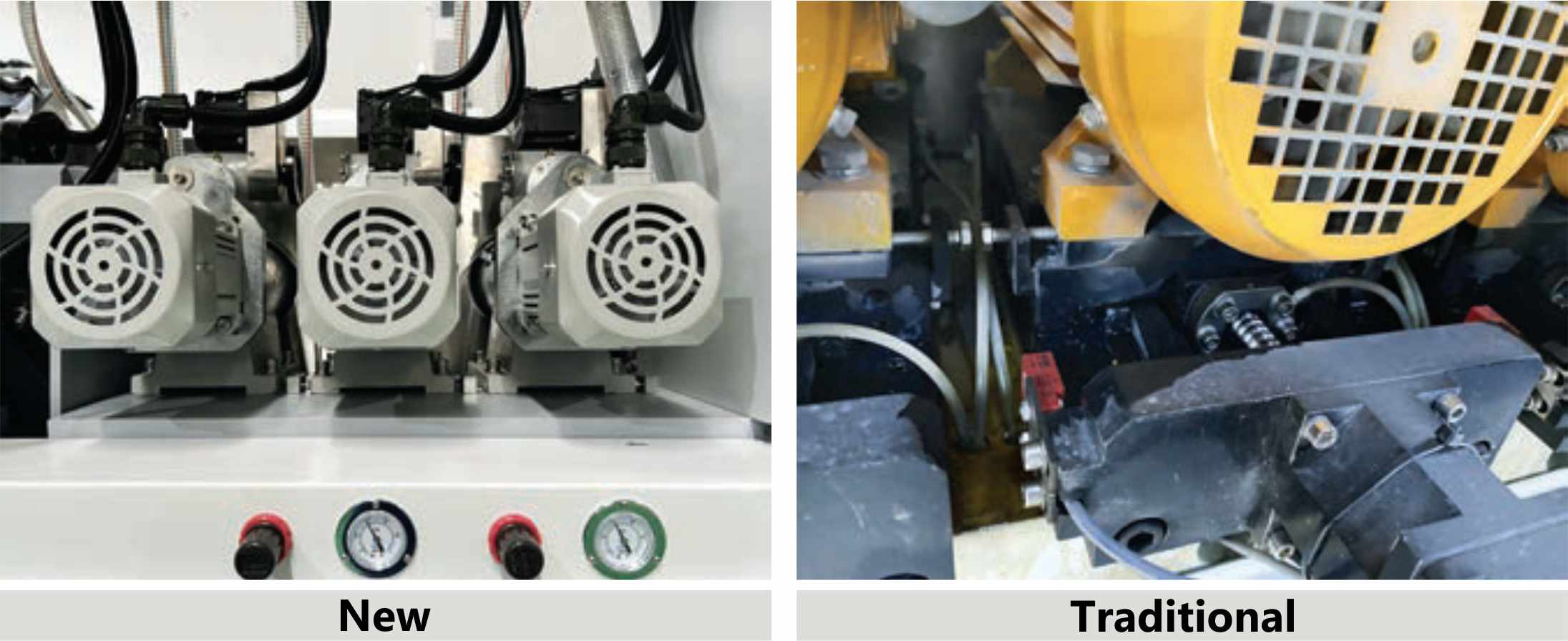

Guangdong Hiseng has launched a new concept double edger, featuring simple design, operation, and maintenance. The updated version completely changes the motor fixing design, leading to fewer issues for customers over time, such as precision problems and maintenance difficulties.

The non-board motor fixing system and unity grinding shaft feeding system represent a revolution in double edger technology. The main shaft, separated from the motor, handles transmission and feeding, while the motor provides power. In contrast to the traditional design where the motor, shaft, and wheels are fixed on the sliding board, the new design reduces resonance in grinding motor parts, minimizing marks on the glass edge for a polished finish.

This structure requires minimal maintenance and is easy to operate.

Unlike traditional sliding boards prone to loosening, the new design adopts nodular cast iron material for the shell and a feeding device with a copper worm gear system. These advanced features, installed in-house with laboratory degree checking tools, ensure precise shaft alignment, strength, and water sealing.

The patented design of an easy join high polymer timing belt guide guarantees straightness even after years of use. Divided into standard parts for easy replacement, the guide is fixed on the dovetail groove, eliminating the difficulty of finding the reference line during replacement. Using a T-shaped belt, the timing belt covers the edge of the guide, reducing the accumulation of glass powder and ensuring consistent belt alignment.

Thickness adjustment control is achieved with FOUR servo motors, ensuring stable, precise, and synchronous adjustments. The upper pressing structures can lift up to 120mm, facilitating easy wheel changes.

The patented design of the straight-line transmission gearbox, installed with a grinding degree gear, requires minimal maintenance, with only periodic oiling necessary. The direct gearbox design reduces the gap between gears, ensuring synchronous upper and bottom belt transmission.

Equipped with the Inovance update movement system PLC and servo control system, the line boasts fast reaction times. Additionally, the update Inovance MD800 VFD system speeds up the motor, reaching a maximum rotation speed of 6000RPM. Each motor has its own VFD, ensuring stable power and minimal interference.

HISENG new concept double edger, understands you better!

Email: hssales4@hsglass.com.cn

Email: hssales4@hsglass.com.cn

Website: www.hsglass.com.cn