Ensuring Safety Amid Fragility: Guidelines for Handling, Storing, and Transporting Glass

It is necessary to pay meticulous attention while handling glass to avoid accidents and injuries.

HANDLING OF GLASS

Need of safety in proper handling of glass is of prime importance. The safety measures must be put in place and rigidly followed when handling glass, both in small and large volumes. Over the time, by experience, certain procedures have been adhered to by glass factories and fabricators. Some of the most pertinent safety practices required are:-

- Wearing of cut resistant gloves and not lifting the glass by bare hands.

- The glass must be lifted by two persons;, single person handling of large size or heavy glass must be avoided. Single person handling can result in twisting and tipping of glass.

- Never lift a glass with bare toe or while wearing slippers. Always wear tight boots. Falling of glass on the feet is most common. Also broken glass on the floor can get in to your feet.

- Use of vacuum grippers should be practiced. Use single pad grippers for small size glass, and double or triple pad vacuum grippers for large size glass. Always use vacuum grippers in pairs.

- The glass should be clean and dry before lifting. Wet glass can slip easily and also the vacuum griper will not grip the wet glass firmly.

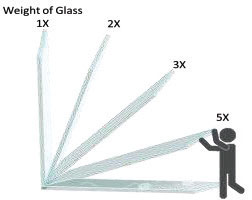

- The lifting capacity of a person must be kept in mind. Lifting glass heavier than the capacity or for longer duration can pose a big problem of fatigue, resulting in slippage.

- All lifting tools like slings, vacuum pads, straps, hooks should have a safety factor of 2-2.5 .Only the properly tested and inspected equipment should be used.

- Worn out, cracked, broken safety equipment, is a serious threat. It should never be used to handle glass.

- Ensure that the path to the handling area is clean; dry (no water or oil spillage) is there. This can be a major hazard and cause of mishap.

- Always wear the proper Personal Protection Equipment (PPE) like gloves, arm guards, safety glasses, boots, helmet, reflective uniform. Do not wear loose clothes to reduce risk of injury.

Storage of glass is required by all glass manufactures, fabricators, processors, resellers including small shopkeepers. Storage of glass is a very specialised work and should be done by trained persons who should be aware of the risk of personal injury and monetary loss in handling flat glass. Understanding of accident prone areas like stairs, sharp turns & corners, and taking effective steps, precautions will minimise or eliminate the accidents. Most important & foremost thing in storage is RACKING. RACKING is stacking of glass at an angle of inclination also known as Lean Angle. The optimum angle of lean should be between 3-5 degrees. The storage can also be done against a wall. The load bearing capacity of the wall should be taken into consideration. The floor on which the glass is being stored should be levelled and even. Uneven floor can result in falling and slipping of glass. The floor should also be strong enough to take the load of the glass. If the floor is not cemented or pacca, there can be chances that the floor might sink with weight. Rodents etc. also are a threat in such a case.

Dos and Don’ts of glass storage are:

- Never drag or slide the glass across the ground. The best way is to lift and place the glass.

- The glass should be placed against each other softly. Impact on one sheet from another can break the glass.

- Use of plastic corners, foam /cork separators will ease out placing and removal of glass sheets.

- Use of various kinds of lifters (Manual, Electric, Pneumatic, Hydraulic), EOT cranes, and Fork lifts should be encouraged to lift and stack the glass sheets.

Precautions required during storage of glass are:

- Ensure that the glass is properly secured and strapped before lifting. Use of extra slings, steel straps, and side slings are an added safety features but a must.

- Never move or stand in front of the fork lift. Keep the glass strapped to the back of the fork lift to avoid it from falling flat to the front.

- Capacity of EOT crane, Fork lift, Vacuum gripers, lifting equipment should be kept in mind. Never ever overload. Periodic check-up of all the lifting equipment and maintenance should be done to avoid any mishap.

- During storage look for defects, cracks, chipped corners in the glass, if noticed do not store such glass. The flawed glass can break or cause injury during stacking and removal.

- Storage area should be well lit and well ventilated. Foul smell, sneezing, nausea can also be the cause of slippage of glass when manual stacking. Large size glasses can obstruct the light and can create dark spots, which can be risky area of accidents.

- ‘A’ Frames are commonly used to stack the glass. It is advisable to stack the glass on both sides of ‘A’ Frame to make it stable and not tumble and tilt due to imbalance.

- Always ensure that the storage place is clean, it is not cluttered and the path is free for movement. Any obstruction can be the reason for tumbling and tripping over.

- No pets in the storage area. Pets can hurt themselves and cause panic resulting in accidents.

- Noise is also a big problem in glass industry. Some machines like belt grinders, Edge grinders, and toughened glass plant create a lot of noise. This noise can make it difficult to hear the instructions and movement of storage vehicles, which could result into collision and mishap. Avoid storage in noisy area.

- The walk way for workers, area for movement of vehicles, trolleys etc. should be away from storage area. These areas should be clearly designated and marked. The storage area should be cordoned and fenced for safety reasons.

- Safety instructions, dos and don’ts chart, caution notices must be prominently displayed. The training of storage area workers must be a regular feature. This will keep them updated and aware of the risks.

- If any shift or slip or untoward thing is noticed in stack, the area must be earmarked as out of bounds. The problem must be attended to on top priority, without any delay.

Transportation of Glass

Transportation of any fragile good is a challenge in itself. When transporting glass lot of care, precautions and alertness is required. Breaking, scratching, chipping, corner breaking during loading/ unloading are very common. The risk of injury and getting hurt or bruised is very high during loading/ unloading of glass on truck or container. When loading on truck/ any vehicle or container, the main problem is the constraint of area. The movement is much restricted due to area availability that result in bruises and cuts very often. Severing of fingers is another serious issue. It is always better to use mechanical equipment like cranes, hoists and other manual lifting devises such as chain pulley blocks, hoists, tripods to minimise human interaction. Many a times the trucks are loaded in a pit, which makes it easier and efficient.

Precautions to be taken for transportation:

Precautions to be taken for transportation:

- The truck or container should be loaded with even load distribution.

- The glass should be secured in wooden crates with steel strapping. Corners of the glass should be secured with cardboard or plastic corner protectors.

- The glass loaded on the truck should be securely strapped, to avoid breakage due to bumps, pits or sudden breaking on the road.

- Foam, cork and other polyurethane separators are placed between the glass sheets, covering of glass by plastic film will help to take care of breakage and scratches due to friction during transportation.

- The truck / container should not be overloaded or driven at high speed. When turning it should be controlled and slow. Manoeuvring on sharp turns, high height speed breakers or multiple speed breakers should be done very carefully.

- Always lay the glass on the edge i.e., in upright position. The edge should be laid on soft wooden logs, with rubber and foam padding .This will avoid chipping at the edges. Horizontal stacking is not recommended.

- ‘A’ frame is used to transport glass on tempos and smaller vehicles. The ‘A’ Frame should be strong enough to take the load. Both sides should be loaded evenly. The ‘A’ frame should be very rigidly secured to the floor of the vehicle. The ‘A’ frame should be levelled to avoid slippage of glass. The glass crates should be strapped with rubber slings very securely.

- Climatic conditions also affect the transportation of glass. Extreme heat or cold can cause thermal shock in the glass. Rain water, dust can also damage the glass. The glass sheets should be covered by plastic sheets before putting in the crate.

- Unloading is equally important. Lot of caution and care is desired while opening the crates. The opening of crates should be done slowly,

- Never stand in front of the glass while opening the crate. Avoid using sharp metal objects with glass as it may break the glass. One sheet at a time should be lifted. The next sheet must be secured before removing the front sheet.

All this and many more precautions are required to handle and minimise the breakage of glass and injury to the human beings.

Have a safe handling, storage and transportation of glass. That is the purpose and aim of this article.

The Author: