Meeting The Challenges of A Transforming Glass Industry with Cutting-Edge Technology

The glass industry has undergone a global transformation in recent times. Glassworks are facing a much more variable request from the market: dimensions and order size are difficult to predict, while delivery times are becoming shorter and shorter.

The new challenge for glass makers is to keep pace, raising productivity and staying competitive. This means investing in new equipment, but mainly reshaping the workshop production flow following lean principles.

Bottero S.p.A. has solutions ready to go for all these challenges based on three main pillars:

– Modular machines and platform concept;

– Integrated systems tailor-made to customer needs;

– Bottero 4.0: A comprehensive suite for machine learning and artificial intelligence.

For more than 60 years, Bottero has been leading the flat glass industry in float and laminated glass with an in-depth and wide range of processing machines, from cutting tables to double edgers and CNC machines.

With more than 200 glass production equipment items, and more than 50,000 processing machines installed around the world for any type of glass, Bottero is the unmissable partner for everyone who wants to cut a piece of glass.

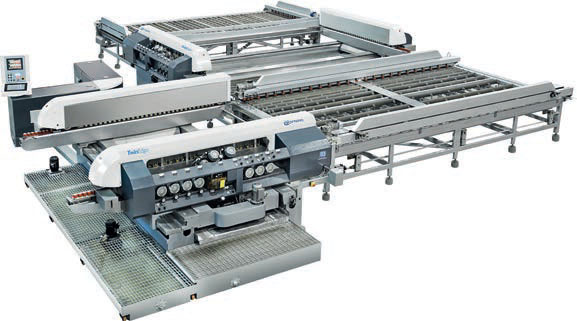

Our product range in cutting (BKM, BCS and EVO) is the widest and most in-depth available today in both stand-alone and dual-line with a laminated glass cutting table, or within an integrated line with stock management systems such as crane loaders or shuttle systems.

Our product range in cutting (BKM, BCS and EVO) is the widest and most in-depth available today in both stand-alone and dual-line with a laminated glass cutting table, or within an integrated line with stock management systems such as crane loaders or shuttle systems.

Thanks to their modular design, our customers can choose several options for their cutting tables, such as the Easy Deletion system with baffle grinding wheel, low-E/TPF removal with peripheral grinding wheel, PPL labeling printer and CO2 laser marking, just to name a few.

Every Bottero cutting table gathers more than six decades of experience and know-how in the glass sector, ensuring not only perfect cutting quality and a user-friendly approach but also remote support and preventive maintenance tools.

Bottero offers a wide range of solutions for laminated glass processing scalable in terms of modularity and automation level, suitable to process laminated glass with PVB (acoustic and/or refrigerated), EVA and special antihurricane interlayers.

Bottero’s R&D department is continuously working to innovate its laminated glass product range to ensure that the company remains the undisputed leader in this field.

The company’s most advanced equipment is the 548 LAM, a fully automated table that can process different laminated glass types with reduced cycle time and energy consumption.

With regards to laminated glass production, Bottero is currently market leader in the assembly line segment with a full range of solutions ranging from entry level, with manual loading and unloading, up to fully automated with automatic PVB unwinding and trimming with an output cycle time of 38s per JS plate of up to 6,000 x 3,300 mm.

Thanks to a great number of patents and more than 25 years of experience worldwide, Bottero offers state-of-the-art nip rolls and furnace area for laminated glass production, suitable for a huge variety of glass size and dimensions. Modularity and scalability are also applied to Bottero’s wide range of horizontal double edgers and vertical edgers.

Of course, double edgers ensure Company News perfect parallelism, squareness and multiple profile finishing, including arrises, engraving and polished radius corners. With Bottero new Flex Edge, customers can really customize their machines with up to 17 spindles per side, with an unlimited range of dimensions up to 12,000mm opening width.

Remote service, cloud connection and preventive maintenance tools are the basic tool set of Bottero edgers.

Bottero is, and has been since 1957, customer-centric. Our Pre-Sales and Sales Department pay special attention to understand customer expectations and limitation to develop the best proposal fitting with customer needs and reducing Total Cost of Ownership (TCO).

Fewer manual operations and more automation have allowed many of our customers around the world to improve their competitiveness and market leadership.

Bottero S.p.A. is the only company worldwide engineering, manufacturing, installing and servicing equipment for both flat and hollow glass.

Email: marco.bellino@bottero.com

Website: www.bottero.com