Enhances Ability To Meet Growing Demand For High-Quality, Large-Format Tempered Glass

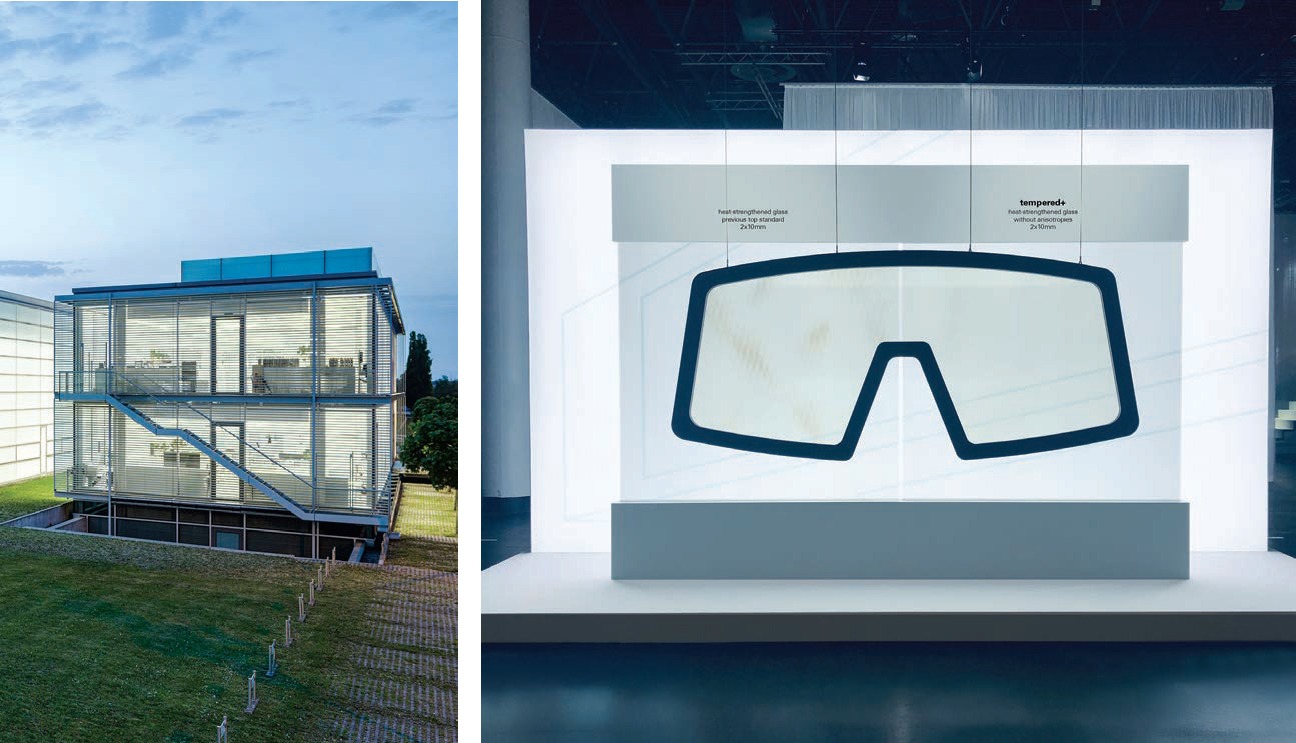

With the launch of an advanced insulating glass production line, sedak increases capacity to deliver premium, anisotropy-free tempered glass to a broader market.

“The demand for sedak tempered+ is enormous. The anisotropy-free glass has quickly established itself in the market. The first projects featuring ‘tempered+’ quality are currently being installed,” says Kevin Berni, Head of Sales at sedak.

“The market confirms that sedak 2tempered+ is the new quality standard in tempered glass. To meet the growing demand, we will also be offering formats that were previously uncommon for sedak. Our goal is to make this premium quality accessible to a broader market.”

The new insulating glass line enhances sedak’s flexibility and productivity, accommodating large-volume orders with standardized pane sizes. Equipped with a rotating and tilting station, the line simplifies the integration of toggle systems, reinforcing sedak’s position as a technology leader in the market.

Anisotropy-free insulating glass

Sedak tempered+ is the first tempered glass without visible anisotropies, produced using a patented tempering process. This process enables the production of heat-strengthened and fully tempered glass with optimal optical clarity, free from the typical shimmer associated with anisotropies. As insulating glass, sedak tempered+ meets high architectural demands for energy efficiency and transparency in glass facades.

About the company

Founded in 2007, sedak has built a reputation as a premium manufacturer of large-format insulated and safety glass, advancing glass as a construction material for facades and roofs.

- On the new insulating glass production line, sedak manufactures insulating glass in formats up to 6 metres in sedak tempered+ quality.

- Anisotropies can be made visible using a polarizing filter. On the left, sedak tempered+ without visible anisotropies; on the right, anisotropies in conventional thermally tempered glass.