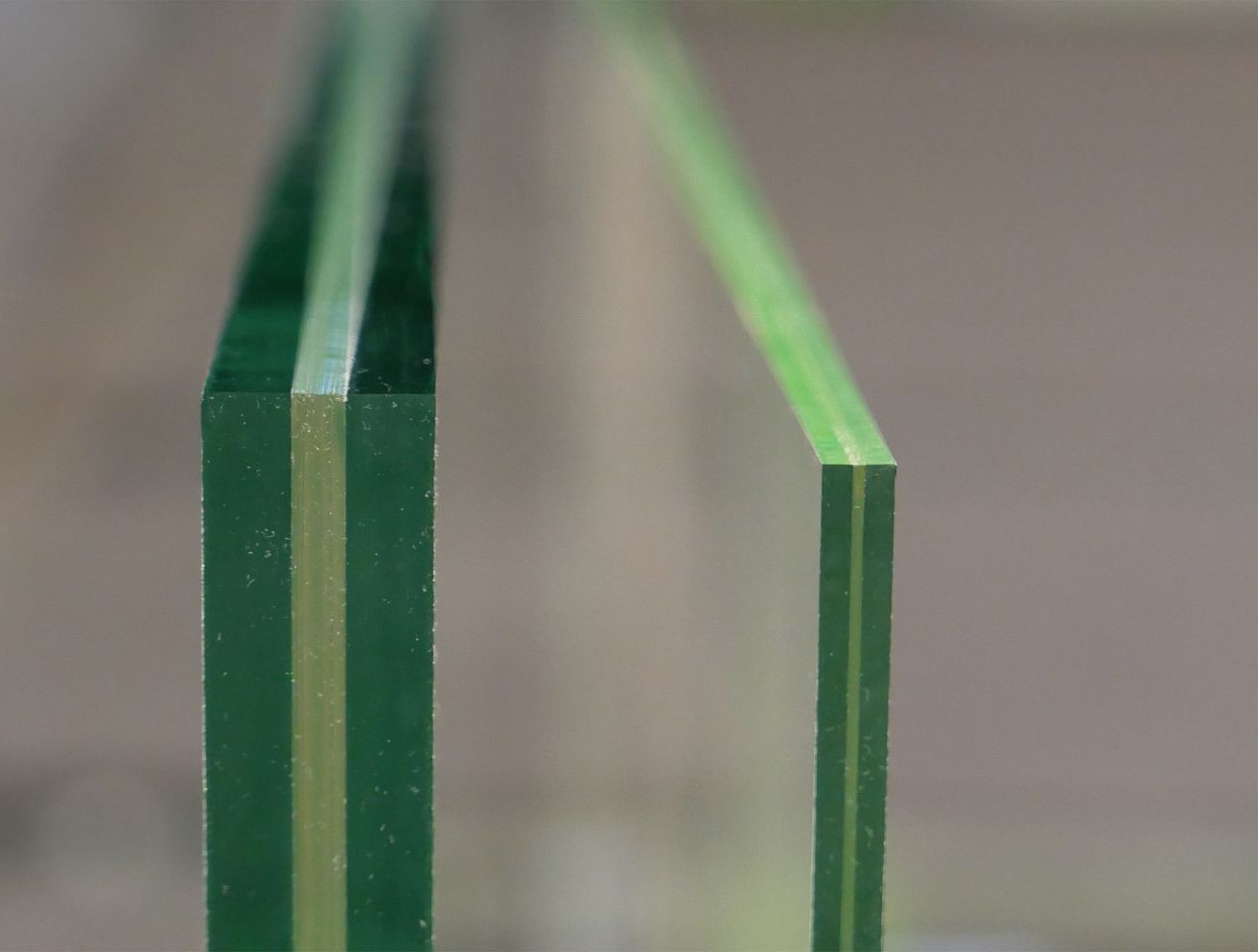

Using a laser makes LSG cutting faster: while heating and separating were previously the most time-consuming processes during cutting, these can be significantly accelerated with the new LSR technology. The impact on edge quality is also positive: the surrounding glass remains cold, thus preventing subsequent delamination.

The thicker the film, the more time is saved

In terms of the overall cutting process, the ProLam LSR equipped with the laser achieves at least 20 percent more throughput. “The thicker the film and therefore the overall composite, the more time is saved,” explains HEGLA Managing Director Bernhard Hötger.

“We can cut a ten-layer film in ten seconds and maintain the maximum quality of the composite edge, thanks to the gentle use of the laser,” Bernhard Hötger continues. The laser diode heater is positioned above the glass, protecting it from dust, lucite, oil and glass splinters. While the performance of infrared radiators is reduced due to soiling, the performance of laser diodes is maintained for a long time. Another effect results from the localised heat input: the glass only gets warm to the touch so that subsequent cuts can be made without any cooling time.

In combination with another existing or new cutting system, the output can also be significantly increased. “The combination of smart cutting distribution, glass-friendly laser technology and just one operator achieves a throughput that meets the highest demands,” explains Bernhard Hötger.

Compared to conventional heating technology, LSR technology reduces energy consumption. The laser diode is only switched on briefly and, depending on the cutting length, is activated partially or fully.

Press officer:

HEGLA GmbH & Co. KG

37688 Beverungen, Germany

Carsten Koch

Tel.: + 49 (0) 5273 905-121

E-mail: carsten.koch@hegla.de