Mishandling Glass Can Lead To Injuries; Simple Safety Measures Can Help Avoid Untoward Incidents

Glass handling accidents are quite frequent in India, making human safety a big concern for the glass industry, but the country still lacks proper guidelines and laws.

Glass is a very fragile material if we talk about annelid glass. When annelid glass breaks, it breaks into very sharp-edged pieces which can seriously injure people and may even may cause death.

Proper handling of glass is a very important part in any glass factory or warehouse. Nowadays, glass manufacturing companies are making jumbo size glasses. These are very heavy, and manual handling of big glass poses risks.

The consequences for mishandling glass can include punctures, crush and strain injuries, severe cuts, amputations and even death.

Observing proper glass handling techniques is a major aspect of safety in any workplace where large volumes of glass are handled daily.

The cost of glass handling equipment is nothing compared to the value of a human life. There is a wide range of glass handling equipment available. It is a request to glass associations and government bodies to come together and frame proper guidelines for glass handling.

Glass handling accidents can be minimised if glass companies ensure that every worker wears

Helmet

Upper arms and shoulder protection Gloves and cuffs’

Apron

Safety footwear

Owner of glass companies have to shell out a lot of compensation to workers who sustain injuries or face any causality during manual glass handling.

Glass Safety Tips for Manufacturers and Commercial Glass Handling

Glass is a fragile material with a plethora of applications in residential and commercial projects. The glass industry is growing with every passing day. More and more glass fabricators and glaziers are entering the market.

However, handling glass in its primitive form is not a child’s play.

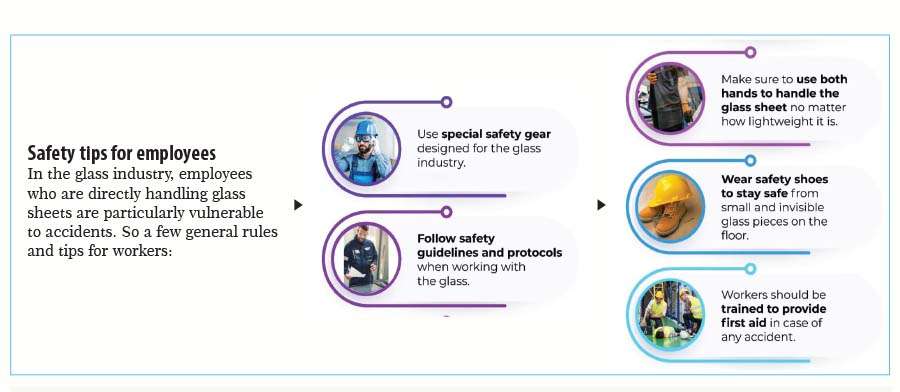

Mishandling the glass sheets can result in severe cuts, injuries, and even death. We can avoid such accidents by following safety measures. The experts have stated strict precautionary rules for handling the glass. Here, we will discuss the safety tips when dealing with glass.

Glass carrying techniques

Workers are often involved in loading and unloading glass sheets. Make sure to carry glass on your side. Use both hands to handle the glass sheet no matter how lightweight it is. It seems easy though, but never carry glass sheet under your arm or over your head. Always use two employees to move larger glass sheets. Don’t rush, move slowly and in harmony with the

other person.

Always wear safety gear before handling glass. Check the glass before moving it. Make sure that it isn’t damaged to avoid any spontaneous breakage. Use the proper hand and body positions to handle the glass. Keep the corners of the glass sheets safe by avoiding bumping into any surface.

When setting the glass on the floor, gently place the long side of the glass first. Prefer placing the glass on soft or padded surfaces. You can also use blankets or other cushioning agents to keep the glass safe.

Handling broken glass

Broken glass is a common sight in the glass industry. Even with safety measures, it’s subjective that you would see some glass pieces on the floor. Therefore, it’s necessary that everyone who enters a glass unit has safety shoes on. Sometimes, small and almost invisible shards are on the floor that are enough to cause an injury.

If you see broken glass, don’t stand or walk on it, even with safety shoes on. Never crush broken glass into smaller pieces with foot or hand. Don’t pick up broken glass with your hands. Never hold on to the broken glass sheet to try and stop it from breaking any further. Move out of the way and go to a safe space.

Working with glass

Working with glass is quite challenging. You have to follow multiple safety guidelines to keep yourself safe. Educate yourself with the safety protocols. Be mindful of the hazards all the time. Be aware of your surroundings and the team members all the time. Inspect each element for any potential hazard before using it.

Keep the simple safety rules in mind and use them to avoid any undesirable situation.

One of the most popular tasks is glass cutting. If you are handling orders of custom cut glass, mirror cut to size, glass shelves cut to size, or tempered glass cut to size, make sure to use safety goggles and gloves.

Creating custom cut glass is trickier than any other job so make sure to take necessary precautionary measures. The manufacturing process of tempered glass cut to size is also quite extensive and grave, so be conscious of the risks.

Glass goes through different manufacturing steps to achieve the custom cut. Different chemicals are also used during the process, some of which can be toxic. Handling such chemicals requires special care that everyone should take.

Handling undesirable situations Even if the work environment is ideal and everyone is following safety protocols, accidents may happen. The possibility of human error is always there. But managing an undesirable situation is what makes all the difference!

Ideally, there should be a doctor or a paramedic’s team on duty all the time

who can handle any such situation. Workers should also be trained for providing first-aid to their fellow colleagues. In case of an accident, take the victim to a safe place. Immediately call a doctor, get help from the related personnel, and give him the necessar y first-aid.

Using safety equipment

Special safety gear is designed for glass industry workers according to their job specifications. The glass handlers usually use cut-resistant gloves, sleeves, and aprons while the glass moulders use heatresistant safety equipment.

Make sure to wear proper safety equipment. Replace any damaged safety.

Prevention is better than cure so never twirl thumbs on wearing the safety equipment. Supervisors should direct strict orders for workers to put on safety gear.

They should ensure that safety gear is functional and the work environment is safe for workers.

In brief!

It’s the duty of the supervisors and directors to educate their staff on risks and safety measures. Workers should receive proper training before getting into the working field. Make sure to meet safety protocols. It’s better to be safe than sorry!

Only cosmetic changes have been made by Glass Bulletin