Making Factories Intelligent, Giving Glass New Identity & Introducing Higher Production Value

Discover how smart glass factories are transforming production with intelligent systems, automation and advanced software solutions.

This evolution has led to improved product quality control, optimized efficiency, reduced energy consumption and labor involvement, enhanced production management, and upgraded safety in production.

Upgrading to a smart factory usually involves three steps.

The first step is upgrading its management, transitioning from traditional extensive management to one that bases investment on market analysis, analyzes capacity according to order structure, determines pricing based on actual losses, and optimizes capacity through lean processes to reduce costs.

This involves

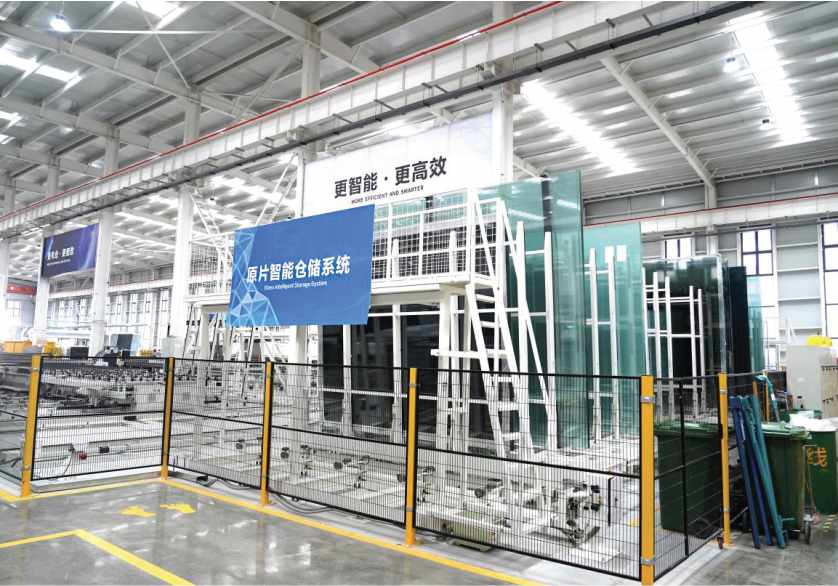

- Intelligent raw glass storage system, intermediate product storage and sorting system, and finished product storage system

- Intelligent marking system and identification system

- Intelligent furnace batching system

- Intelligent sorting and pairing system

- A utomated conveying mechanism

The third step is functional machines upgrading. Truly intelligent machines represent the ultimate challenge for a smart factory, requiring an in-depth analysis of processes and absolute control over production. This involves fully automatic edging and preprocessing equipment upgrades, an intelligent tempering furnace, and fully automated smart insulating glass production modules.

Based on this three-step approach, we can start a new journey towards intelligence, starting with software.

Software upgrade

ERP serves as the core database for a deep glass processing factory, covering a series of functional modules ranging from sales orders, procurement, material management, production, and dispatch to finance.

In contrast, MAC’s ERP is a specialized system developed specifically for deep glass processing equipment. It seamlessly manages and tracks each piece of glass in complex orders.

A factory-wide ERP+MES system can even effectively manage each piece of processing equipment, optimize orders, and decompose them into independent equipment instructions, processing them in a language the equipment can understand.

By extracting production data from the ERP+MES system, calculating the effective capacity of each individual piece of equipment and the actual cost of each order becomes much easier.

The logistics optimization

Next is the logistics optimization stage. A typical example of this is optimizing the process from raw glass storage to cutting.

This process acts as a powerful brain for the glass warehouse, enhancing the optimization rate by 3 to 5 percent by combining online and offline glass storage information. Through an automated raw glass conveying system, the glass can be safely and efficiently transported to the cutting line.

The intelligent cutting line represents a significant evolution from the traditional cutting line. The traditional cutting line can only cut according to optimization packages, while the cutting line in an intelligent factory assigns an identity to each piece of glass. This can be achieved by adding an independent laser marking machine or replacing the traditional cutting line with a two-in-one laser marking and cutting machine.

At the same time, an intelligent connection from cutting to edging can also be achieved.

Email: solution@macglastech.com

Website: www.macglastech.com