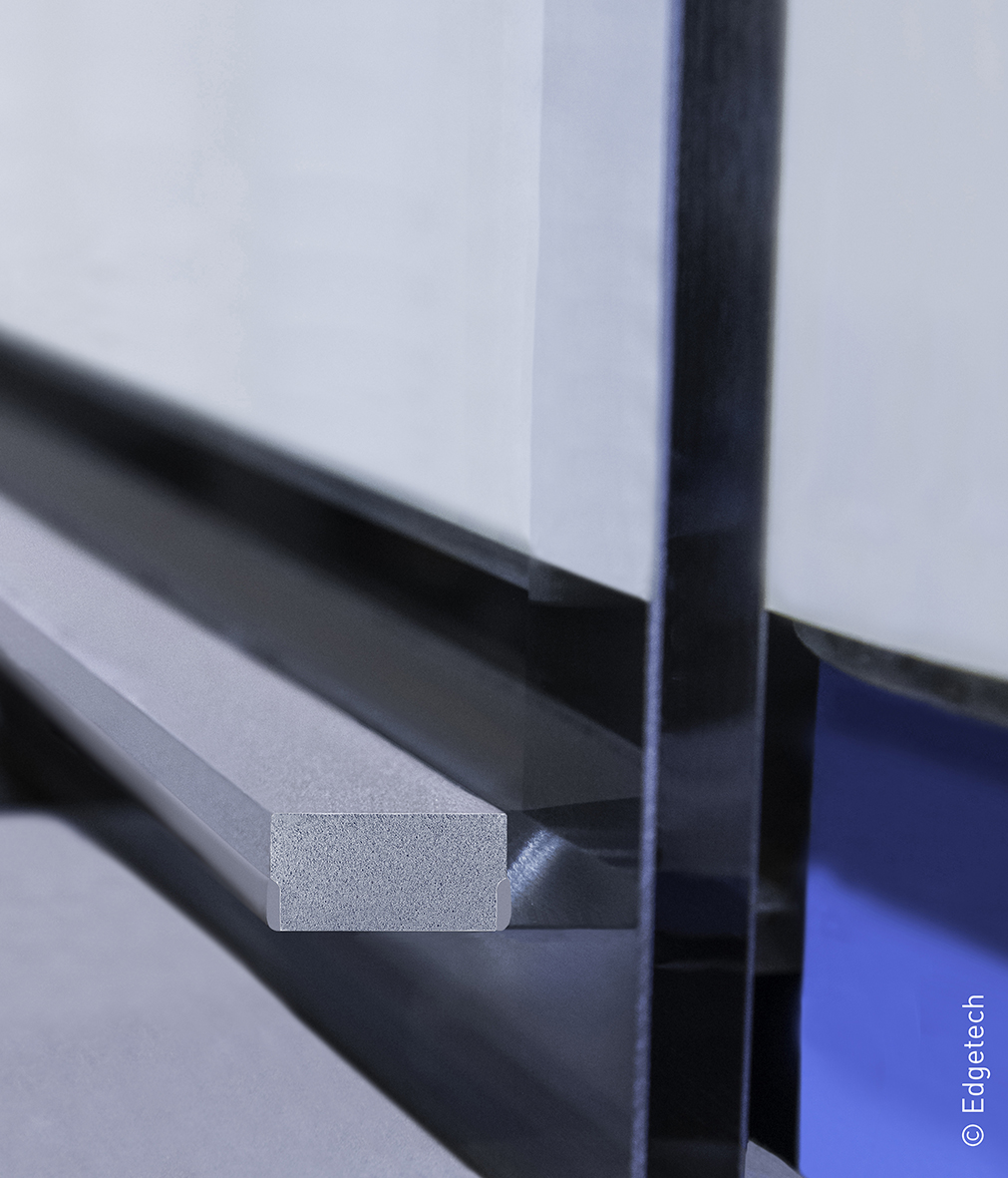

For the new college building in downtown Berkeley, an architect’s wish became reality: the fully automated and therefore economical production of a completely grey insulating glass edge seal. A light grey Super Spacer® bar is also part of the elegant facade solution.

“The details are not the details. They make the design.”The vast majority of architects will agree wholeheartedly with this famous quote by Charles Eames. Details turn a good design into a great one and are often the key to turning an idea into reality. In the case of the Milvia Street Campus, a new school building for Berkeley City College in California, a small detail makes all the difference: an insulating glass edge seal, in which all components from the spacer made of textured silicone foam to the butyl and silicone seal are grey. When the facade is finally installed, the silicone joints will also follow the colour concept. Although the edge seal cannot be completely invisible, its colour should blend in with the glass as far as possible, giving the structural glazing facade a light, inviting transparency.

Ultimate goal: maximizing daylight incidence

The 6-storey building replaces an existing building in Downtown Berkeley at 2118 Milvia Street. In addition to classrooms, it will house art studios, a library and areas for student support and administration. The building was planned by Ratcliff Architects as part of a design-build partnership with XL Construction. CS Erectors is responsible for the facade consultation and installation.

Due to its location in a densely populated urban area, maximizing the amount of daylight entering the building is a top priority in order to optimize the energy efficiency of the lighting. “We wanted to create a place where people feel welcome and cared for, which is why the entire design is open and transparent,” explains Patricia Alarcón, Head Architect at Ratcliff.

The transparent glass facade provides a view of the artworks inside, which are intended to further enliven the building. According to Ratcliff, the design responds to the urban context, offering visual transparency and a system of interconnected social spaces that emphasize user interaction and collaboration. A rooftop terrace on the sixth floor provides a place to relax outdoors between classes.

Insulating glass with many functions: aesthetic, discreet and bird-proof

Around 1,500 m 2 of insulating glass units with ipasol platin 47/27 solar control coating were manufactured by the AGC Interpane plant in Plattling according to the specifications of the Californian architects. A completely grey edge seal was intended to lend the structural glazing facade an appealing lightness, as the homogeneous, monolithic impression is not interrupted by black lines. In the lower area, the glass panes are screen-printed to around 30 cm to maintain the harmonious appearance of the facade and at the same time partially obscure the view into the interior of the building. Position 5 on the glass pane is largely printed with an etched pattern that is perceptible to birds to prevent collisions.

Fully automatic butyl changes in the insulating glass line

“Although a completely grey edge seal is not the standard, it is becoming an increasingly important topic for many architects when it comes to structural glazing facades for aesthetic reasons” confirms Daniel Bruckelt, Production Manager at AGC Interpane in Plattling. “The architects also wanted a grey edge seal for some of our major projects, such as the modernization of Two Bryant Park in New York and The Shard in London. Although we can change the colour of the Super Spacer from black to grey at will, it was of course unthinkable that grey and black butyl would be extruded through the same nozzles,” he continues. Until then, the simple and fully automatic changeover between different coloured butyl within the insulating glass line was not possible due to the technology. Glaston therefore developed a customized solution for AGC Plattling that is unique in the world. “The double-head applicator for the automatic application of Super Spacer spacers with butyl application on both sides was given a butyl switch, so to speak. We can now also apply grey butyl fully automatically via a second feeder without any effort,” explains Daniel Bruckelt.

Super Spacer® supports efficiency and quality in fully automated insulating glass production

“Customers such as AGC Interpane show that the Super Spacer bar system is optimized for automated insulating glass production – both because of the precise, sharp-edged application and because of the production-related advantages,” says Joachim Stoss, Vice President International Sales IG at Edgetech/Quanex.

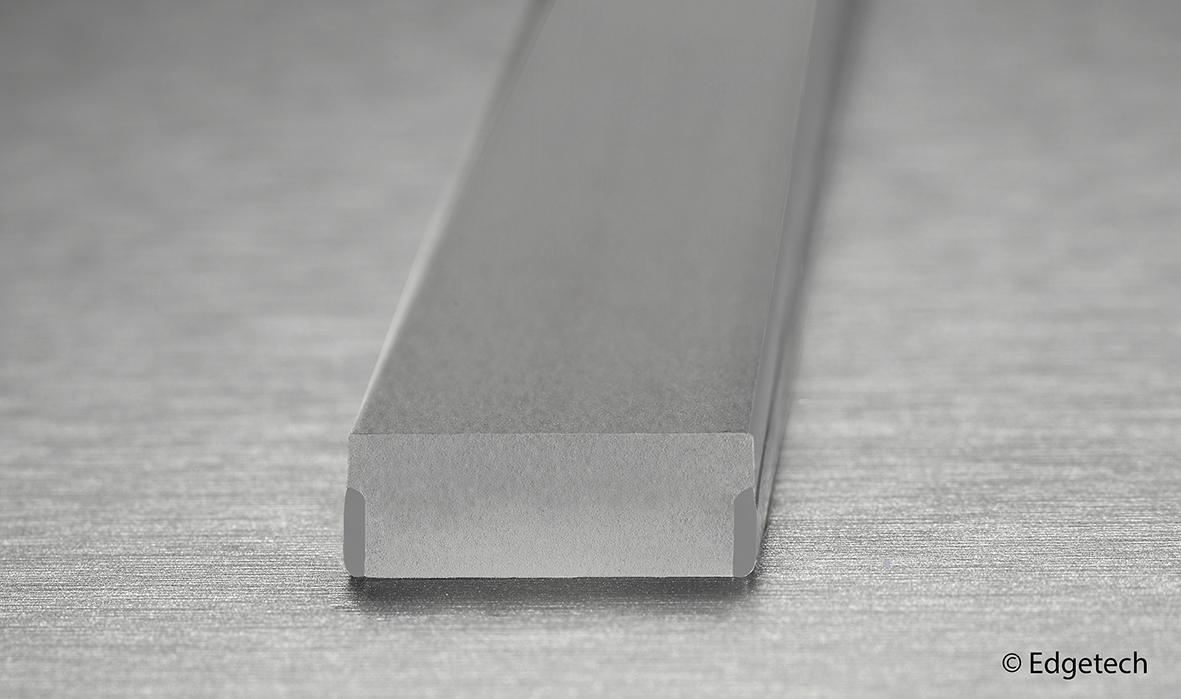

The flexible Super Spacer® essentially consists of a structural foam. As it is applied from the roll, process steps such as cutting to size, bending, and filling with desiccant are no longer necessary compared to rigid systems. In contrast to thermoplastic systems, it is not applied under high heat and therefore high energy consumption. The properties of flexible spacers are also helpful in the production and handling of large and heavy panes with gaps between panes of up to 32 mm (up to 28 mm in automatic processing). As the edge seal is immediately stable after application, it does not move when lifted and the insulating glass units can be packaged immediately after production. Super Spacer® can be processed with all common sealants such as hot melt butyl, polyurethane, silicone, and polysulphide. The manufacturer’s guarantee is not linked to the use of a specific secondary sealant.

Super Spacer® also scores with another detail: the metal-free warm edge technology optimizes the efficient thermal insulation of buildings. With a heat transfer coefficient Ψ of up to 0.029 [W/mK], the warm edge Super Spacer® is one of the most energy-efficient spacers and is, of course, passive house certified.

About Edgetech Europe GmbH, A Part of Something Bigger

Edgetech Europe GmbH, located in Heinsberg, Germany, is a fully owned subsidiary of Quanex Building Products Corporation, (NYSE: NX) a global, publicly traded manufacturing company primarily serving OEMs in the fenestration, cabinetry, solar, refrigeration and outdoor products markets. Edgetech Europe GmbH services markets in continental Europe with a total of 490 employees and 17 extruders. We are “A Part of Something Bigger” by improving the performance and aesthetics of end products through continuous innovation, helping customers achieve greater production efficiencies, and giving back to communities where we operate. Visit quanex.com for more information.

Contact

Press Agency

Interview International

Ingrid Hecht

15, rue Martin Luther

67000 Strasbourg, France

Tel: +33 (0)388.1555.88

info@interview-international.fr

Edgetech Europe GmbH

Gladbacher Straße 23

52525 Heinsberg, Germany

Phone: +49 (0)2452.96491.0

info@edgetech-europe.com

SUPERSPACER.COM