By introducing the advanced technology and equipment of Yinrui Intelligent, the whole process from glass cutting, edging to tempering has been realized. With only 4 persons on the production line, 1,500 square meters of tempered single-piece glass can be produced per shift.

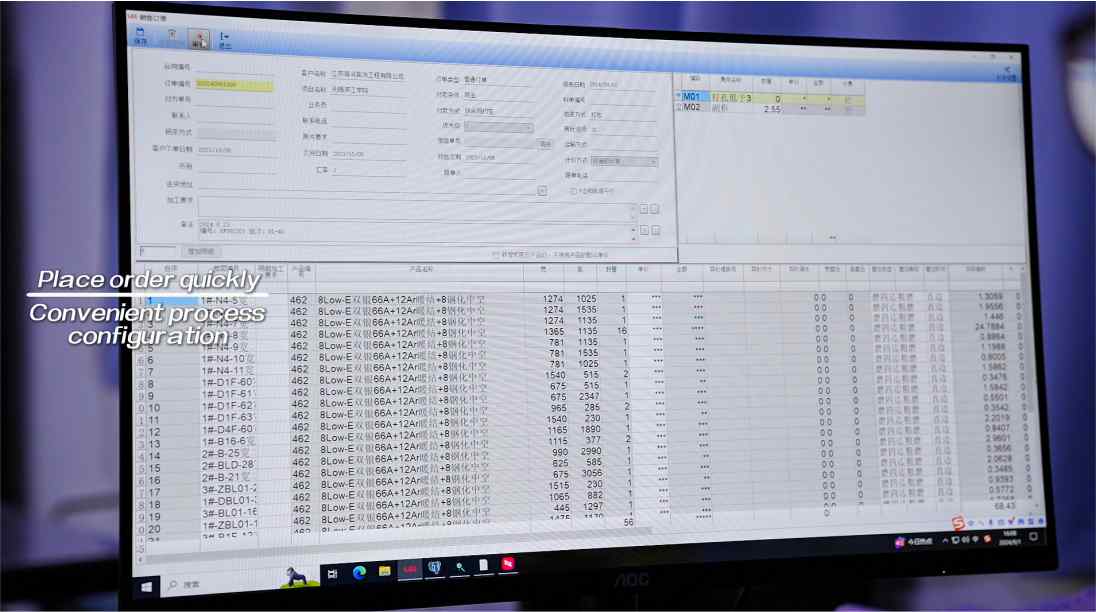

In the smart factory of Wuxi Tianyi Safety Glass, the introduction of the ERP system has become the key to improving management efficiency. The system supports online quick ordering, automatically matches inventory and production resources, and greatly shortens the order processing cycle. At the same time, the ERP system also provides flexible process configuration functions, which can automatically generate the optimal production plan according to customer needs, ensuring that every order can be accurately and efficiently executed.

In order to maximize the use of raw materials, Tianyi Glass’s smart factory uses an advanced glass cutting optimization algorithm. This algorithm can analyze the size, thickness, quality and other information of the glass in the original library in real time, which increases the glass cutting optimization rate by more than 3%, so that every piece of glass can be used to the fullest.

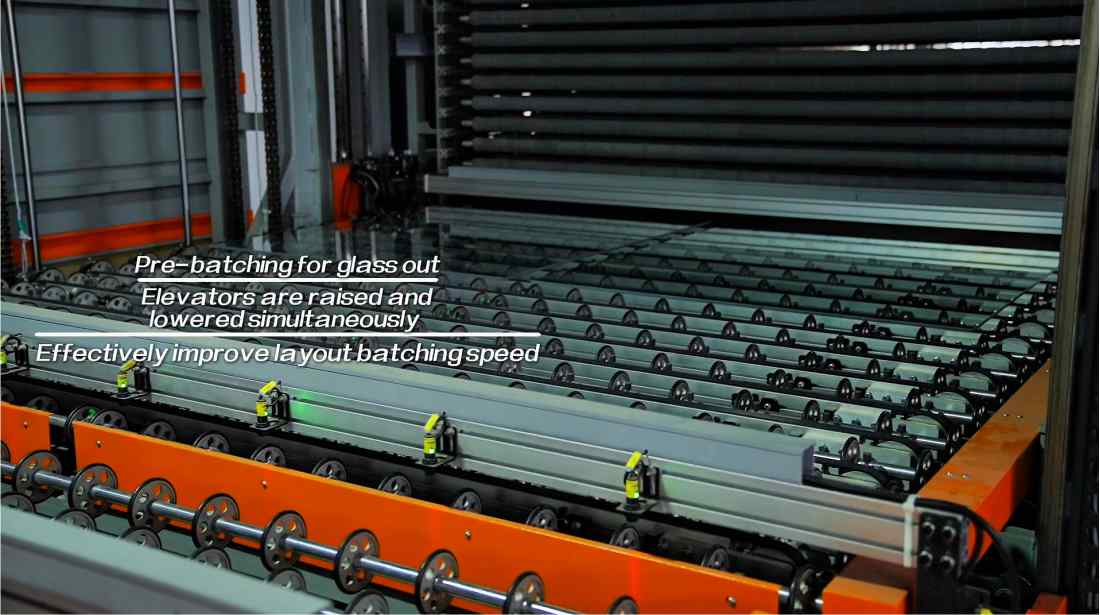

Yinrui Intelligent has equipped Tianyi Safety Glass Company with a 35-layer double buffer storage system with large-capacity storage capacity. The double buffer alternating working mode can ensure that the grinded glass can be seamlessly transitioned to the tempering furnace, which not only enhances the continuity and stability of the production line, but also improves the company’s ability to cope with production peaks and emergency orders.The smart factory project built by Yinrui Intelligent for Tianyi Glass Company has achieved a number of technological breakthroughs and optimizations in the flexible production process of “cutting to tempering”. The successful acceptance of this project not only brought significant economic benefits and production efficiency improvements to Tianyi Safety Glass, but also set a new benchmark and model for the entire glass deep processing industry.