Software Has Been Independently Researched And Developed By Company Since 2010

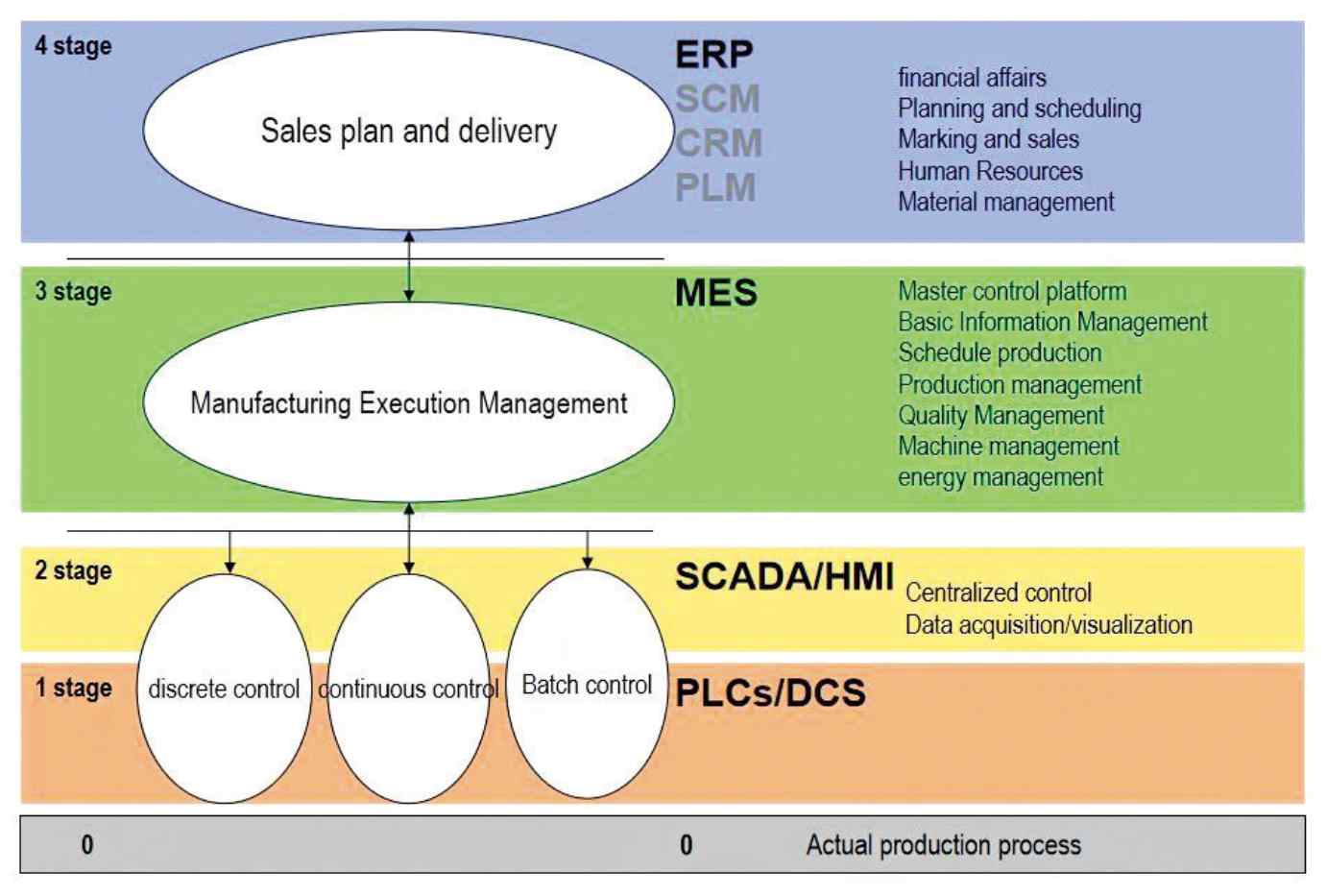

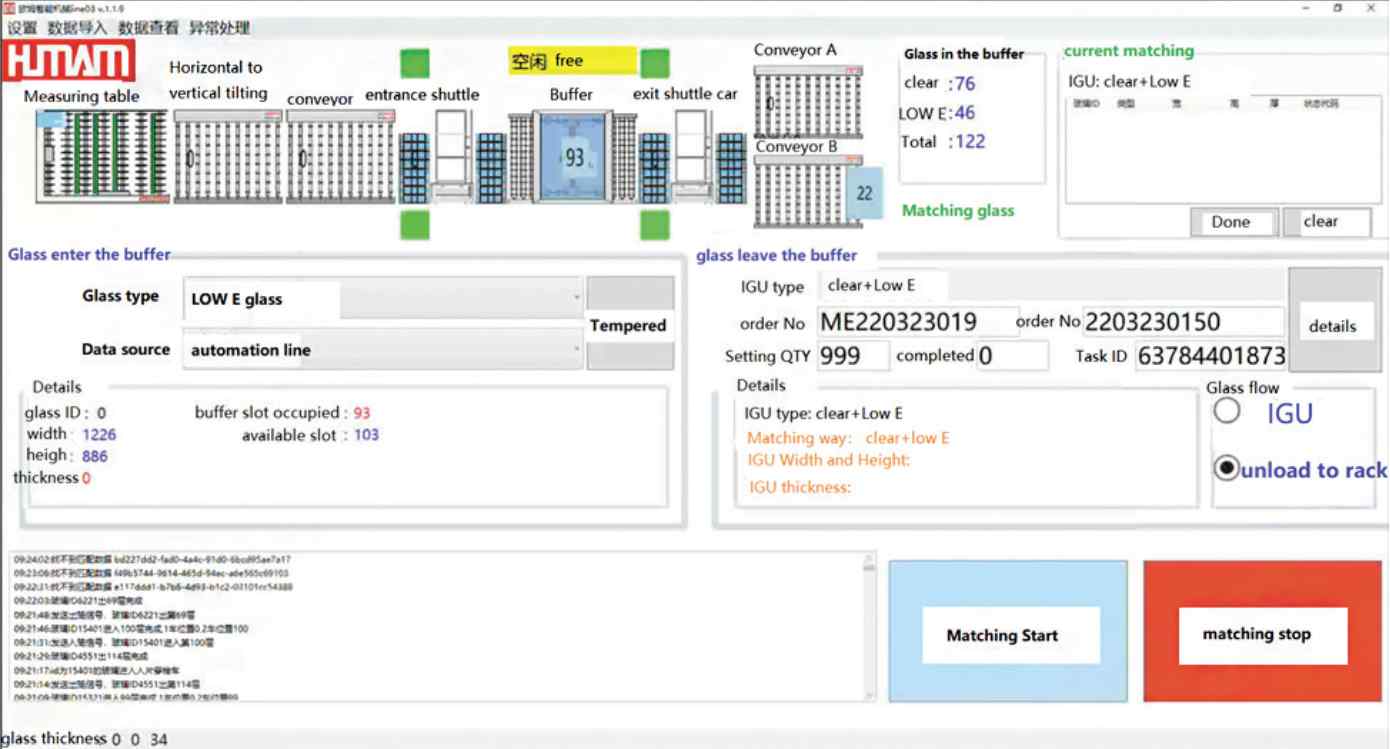

HUMAM MES streamlines the glass manufacturing process, ensuring real-time data integration and optimized production from start to finish.

HUMAM MES software, starting from the float glass storage system—the first step in intelligent factory equipment and systems—has been independently researched and developed by the HUMAM team since 2010. To date, over 100 sets of intelligent storage systems have been put into use.

Since 2019, in response to higher market demand for reduced labor costs, increased safety, and improved glass quality, the HUMAM MES control software has been upgraded to manage the entire factory. This upgrade includes about 80 sets of laser marking systems—keyequipment in smart factories.

Additional upgrades include horizontal sorting systems before edging and tempering furnaces with automatic batching systems and vertical sorting systems for autopairing the low-E coating and clear glass for IG lines.

In 2021, it was applied to Foshan SG for a jumbo-size production line, including a jumbo-size shuttle storage system for both raw glass packages and finished glass. The 6000x3000mm vertical sorting system allows the whole line to operate with only five operators, producing 1500SQM IGU every day. This setup represents the most advanced glass processing factory for high-end curtain wall doors and windows.

Following these successes, HUMAM has gained increasing customer trust and support for smart factory projects. The HUMAM machine and MES control system have been supplied to SYP, XYG, WXXL, and customers from the USA, Europe, the Middle East, Vietnam, and Russia.

Ms. Vanessa Luo

International Sales Manager,

HUMAM Intelligent Machine Co.,Ltd.

Website: www.humamglass.com