Climate change is the biggest challenge of the present century. In order to achieve the necessary reduction in CO2 worldwide and slow down the noticeable global warming, our industry is also facing major upheavals.

Instead of leaning back and claiming that “we don’t have a problem with our machines, since our machines and systems only contribute to a very small proportion of the emissions”, we have created concepts for developing machines that considerably improve the carbon footprint of glass. We were also able to persuade AGC that our idea was good, and built the first machine called IG2Pieces as a prototype for them. This was only made possible by the excellent collaboration between HEGLA and HEGLA New Technology and above all, by the personal commitment of the employees involved, to whom we would like to express our sincere gratitude.

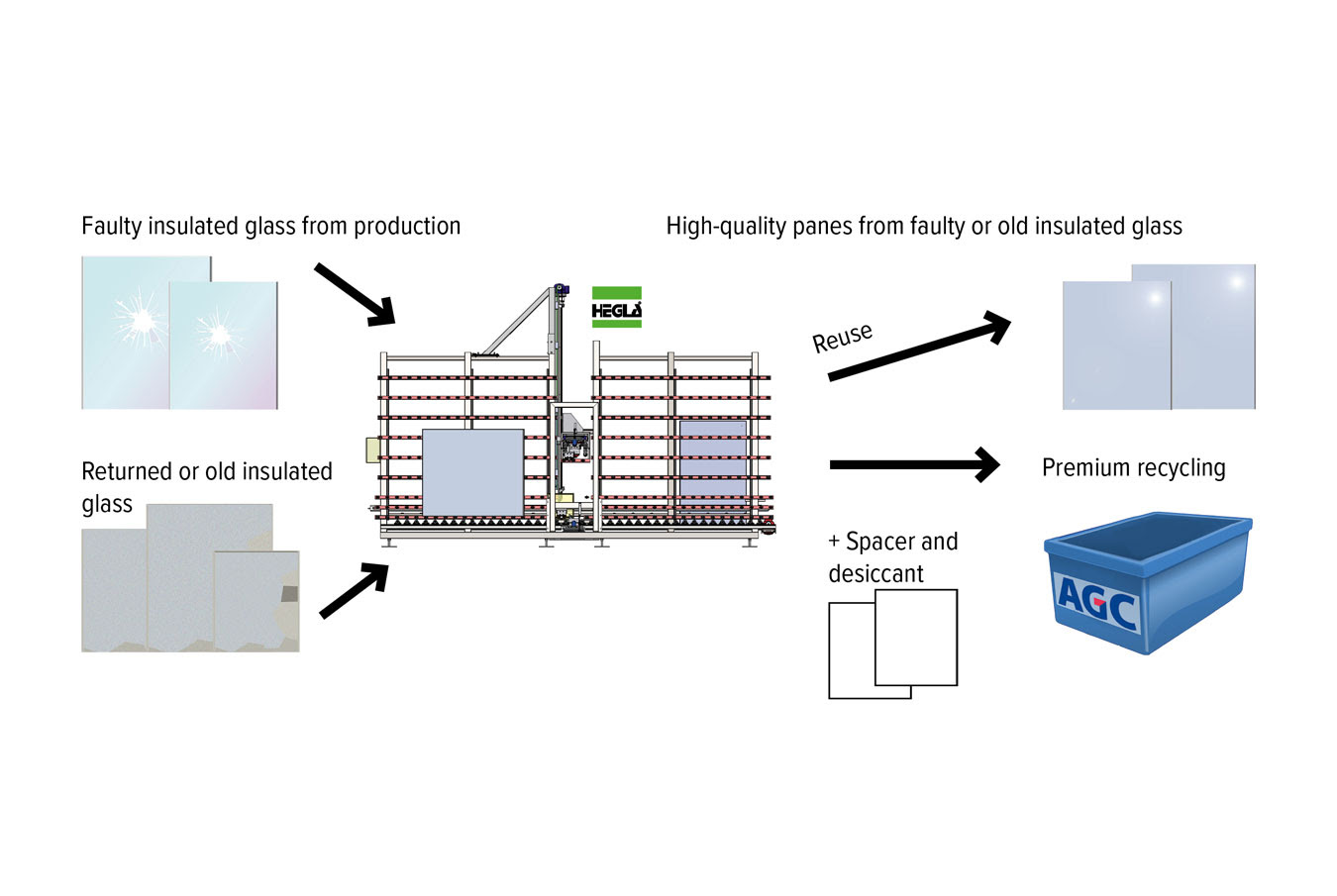

Our joint success is that the machine not only serves a forward-looking purpose. At the same time, it also offers our customers a wide range of options:

- repair of freshly produced insulated glass elements by disassembling and reassembling them (for example, a pane is scratched, the frame is crooked or the famous fly is in the space),

- unmixed production of glass shards from insulated glass, resulting in good shard quality that permits the shards to be melted in the flat glass furnace and save around 0.3kg CO2/kg glass scraps and

- a gentle separation process that enables panes to be reused and generates virtually CO2-free second-hand glass.

IG2Pieces is only the beginning of a whole series of machines that still needs to be developed. We are already working on the next steps. We have already talked to many customers and received more than positive responses from all of them. Many customers have asked for offers and would like to test our machines themselves as quickly as possible. With the PaneUpcycle concept of recycling, we have not only hit the mark with our customers, but have also taken an important step towards CO2 prevention – a step we are very proud of.