In 2019, we founded HEGLA New Technology with the aim of integrating new trends in digitalisation and glass as a means of further increasing the innovative power of the HEGLA Group.

Markus, in a few words, would you please tell us what you are currently working on?

These exciting projects are what come to mind from the recent past:

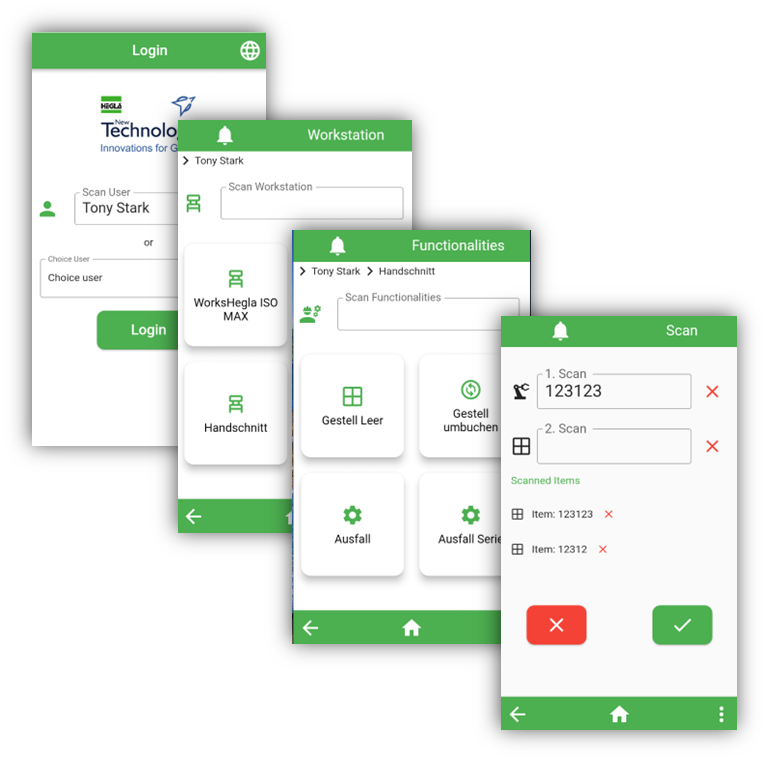

- A modern mobile app for production employees in the glass industry in conjunction with HEGLA-HANIC SmartScan,

- The development of standards and test applications for OPC UA and the asset administration shell, which is revolutionising digitalisation,

- Technological developments for HEGLA TaiFin tempering furnaces,

- Further development of our Shopfloor Assistant app, which HEGLA also uses.

Those are interesting topics indeed. Would you mind using SmartScan as an example to show me what you’re doing in detail?

In the past, simple barcode scanners that, in the best case, beep and have an LED, were typically used in production. This means that the production employee scans a pane at the end of the cutting table or a finished piece and then the data are displayed on a stationary PC. Employees only have a limited overview, since they always have to walk to the PC in order the view the current status. We thought about how we could scan on the one hand and enable the information to be displayed on different devices, like a smartphone or smartwatch, on the other. Together with HEGLA-HANIC, we started to develop the initial implementation. When designing the functions, we constantly asked ourselves which ones were necessary for operators and, at the same time, which information would be useful. This led to a completely new user interface. The key advantages for operation: instead of working with a cumbersome device that can only be used for scanning, SmartScan also provides information on panes and processes. It is actually a digital assistant.

Do you think that this innovation could also be interesting for production at HEGLA?

Yes, of course! The aim is always to document work steps, to know the current location of workpieces and report material consumption. SmartScan can simplify these processes. With the aim of digitalising HEGLA in Beverungen, we are already in close contact with Andree Kleinitzke and Stefan Asche. If you have suggestions and wishes related to this topic, we look forward to your feedback via markus.schoisswohl@hegla.de.