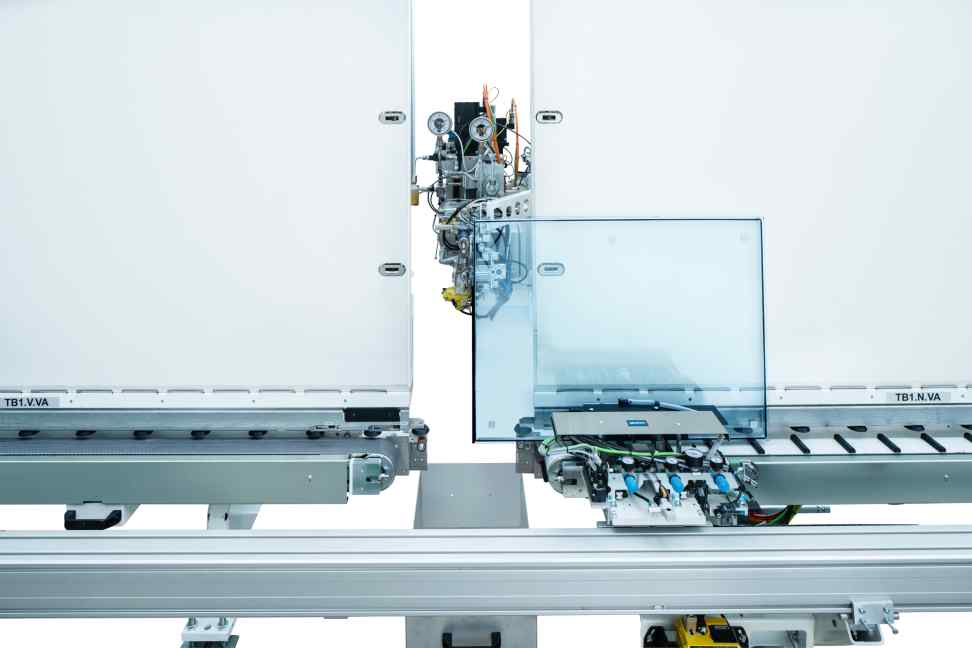

We recently unveiled its latest sealing robot for insulating glass units – Glaston ACTIVE’SEALER. This innovative addition expands our sealer product family, complementing the high-end Glaston SPEED’SEALER and bridging the gap for the mid-range market. Its excellent mixing and dosing quality is based on all our approved two-component sealants.

ACTIVE’SEALER is based on our established gear pump dosing technology, which has been serving customers reliably and cost-effectively for decades. The high-precision system ensures excellent sealing quality and allows for immediate volume adjustment when changing the sealing depth. The special nozzle-spatula system guarantees uniform sealing in corners. Plus, operators can easily fine-tune the material ratio electronically from the control panel to achieve optimal mixing quality. For varying spacer widths, the nozzle is centered automatically, and the quick-action lock system leads to a fast nozzle exchange.

ACTIVE’SEALER features a user-friendly and intuitive graphical interface for easy operation. It is available in three configurations: Light (max. 2.8 x 3.5 m), Standard (max. 2.8 x 4.0 m) and Extended (max. 2.8 x 5.0 m).

For more information and technical details, please visit: Glaston ACTIVE’SEALER