Panels and collectors play an important role for the energy revolution. An increasing number of manufacturers and distributors of modules and substructures raise the question of product stability and quality. Several standards exist for the mechanical load capacity of photovoltaic and solar heat systems. euroTECH Handling GmbH in Rosenfeld developed a testing device for this purpose many years ago, which can be used to test far beyond the current standards.

More than 15 years of experience

The Fraunhofer Institute approached euroTECH back in 2009 with a request to develop a testing device for measuring the tensile and compressive forces of panels and collectors. A short time later, TÜV Rheinland also contacted the vacuum technology specialists. Both testing organisations were originally only looking for suppliers of suction cups, in order to set up their own test bench for photovoltaic modules. Soon it became clear: euroTECH had all the expertise needed to produce a complete testing device– including control system and euroTECH started to develop and produce a testing device that met all requirements.

Specially designed for photovoltaics and solar heat energy

Solar modules and collectors are installed in exposed locations and have to withstand many environmental impact. Wind, ice, snow loads and hail were just some of the factors that put the modules to the test. The euroTECH testing device simulates and documents reliably such impacts in form of defined forces, cycles and times so that customers can avoid any bad surprises. Over all, the testing device is distinguished by huge flexibility and scalability. Different variants and options are possible – depending on requirements and customer wishes.

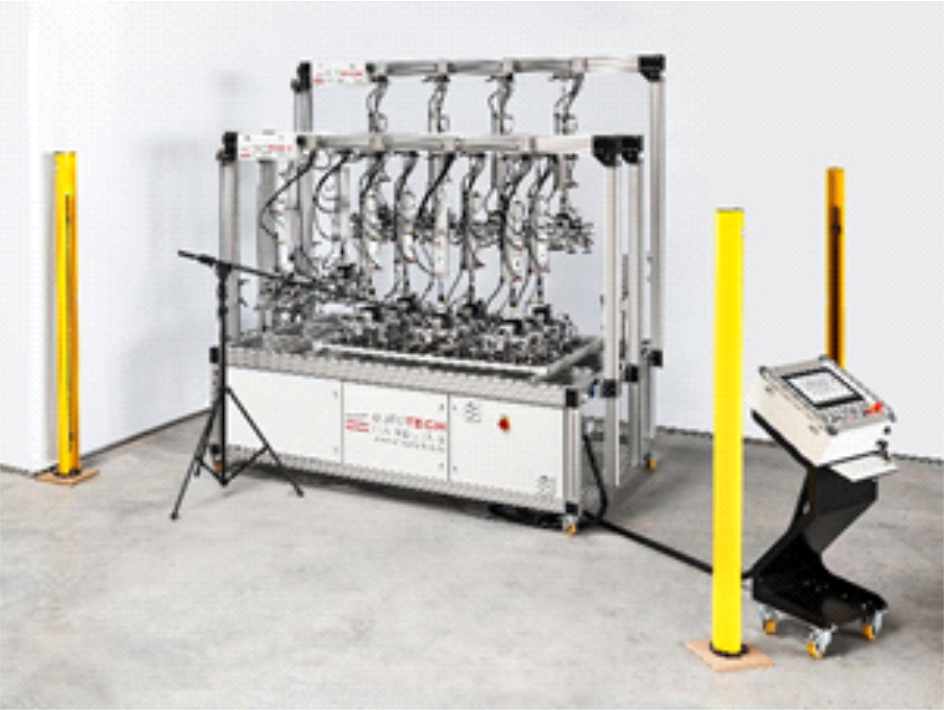

Know your limits and reserves

Common to all variations are the aluminium bridges – which can be adapted to different module sizes using linear guides. The combination of suction cups and compressed air cylinders are designed according to the individual tests and customer requirements. Depending on the installed suction cups and cylinder units, different pressure forces result, which are specified in Pascal depending on the module area. This is crucial, as the test force is specified as pressure in Pascal (Pa). The standard specification for PV modules is 1,000 Pascal (dynamic). Many of our customers of solar testing devices want to achieve significantly higher values with the aim to increase quality and to reduce material costs. In order to reach the load limit at which the module actually breaks, euroTECH has already realized test forces above 13.000 Pascal.

Control and logging safeguarded

Control and logging safeguarded

The corresponding software for controlling the testing device and for analysing and documenting the test procedure has also been developed under the direction of euroTECH. With its intuitive visual navigation, this software is easy to use and the corresponding protocols for the relevant tests can be put out at the same time. This provides euroTECH users with a complete solution for testing solar modules and collectors.

Versatile in use

The versatility and scalability of the testing device was clearly demonstrated when two special requests came up: A customer from Italy wanted to test solar heat collectors, while a German manufacturer of substructures aimed to test a complete unit existing of different panels and substructures. Both was easily realised with slight modifications to the basic testing device.

Latest technology and modular design

The current version of the solar testing device includes innovations such as IO-Link control, a temperature check of the module, a room humidity measurement and an electrical continuity measurement. Another innovation is the use of two compressed air cylinders to optimize dynamic testing and fast-load-changes. This allows frequencies up to 4 Hz to be achieved instead of the required standard of 0.1 Hz. By using double cylinders, the compressed air requirement during the test is significantly reduced.

Safty first

Every euroTECH solar testing device can be ordered with an optional maintenance and calibration package which guarantees that all settings are checked and adjusted. The required occupational safety is guaranteed by safety equipment such as protective walls, safety fences or light barrier.

Characters including spaces: 4,320, 3 images, reprint permitted

Company profile:

euroTECH offers handling and transport solutions in the field of vacuum technology. The company develops and produce customer-specific vacuum systems and components for automated handling tasks. Thanks to the euroTECH modular construction system, the components can be flexibly adjusted to meet individual customer requirements and spare parts can be installed in a quick and cost-saving manner.

Contact for the editorial team:

Monika Schuster

euroTECH Handling GmbH

Maybachstr. 7 | 72348 Rosenfeld | Germany | et-handling.de

T +49 7428 939120

presse@et-handling.de