Compared To Conventional Warehouse, Hegla Compact Storage Systems Can Increase No. Of Rack Positions

With direct access to additional types of products and lower handling costs, a compact storage system for glass contributes to improved workflows and greater flexibility.

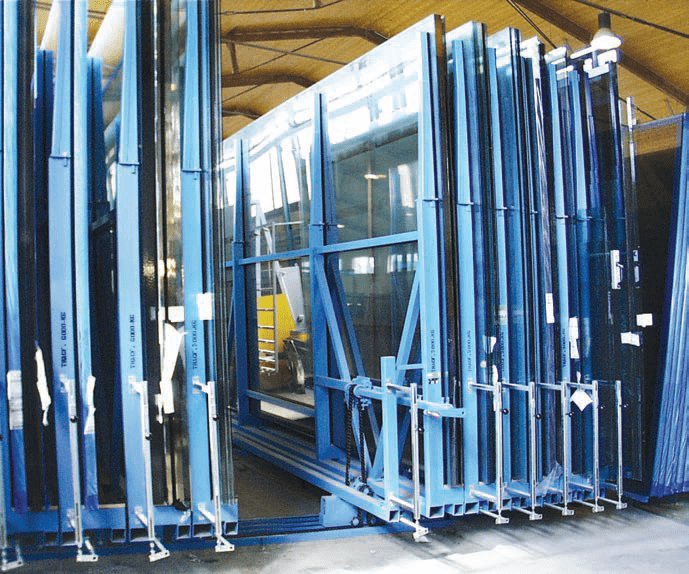

Individual storage positions are mounted side by side on rails to save space. For removal, an opening is created either manually or automatically so that the glass can be removed quickly without prior resorting.

More rack positions and direct access to diverse products

In comparison with a conventional warehouse with A- and L-racks, compact storage systems can increase the number of rack positions many times over. Smaller compartments offer the option to store a greater variety of products. Larger storage positions have the space required for accepting larger quantities of one type.

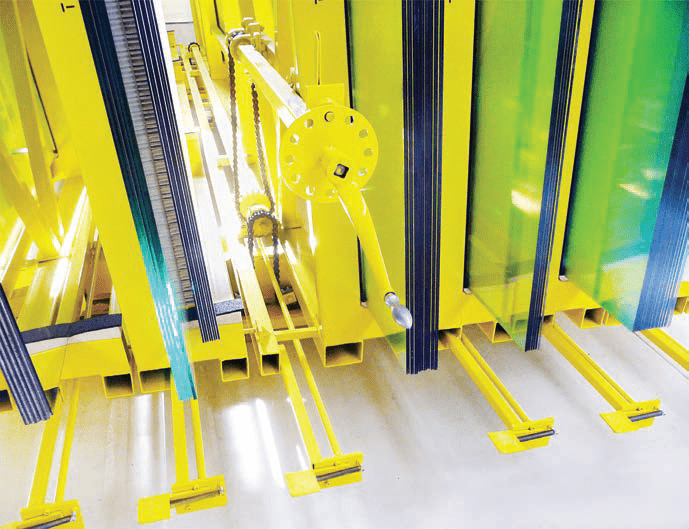

Be it manual, motorised or wireless controlled – compact storage systems can be harmonised to satisfy individual customer needs. The KPL-MZ manual storage system was designed for companies that require smaller quantities and a greater variety of products.

It is also suitable for the provision of panes in special cutting. To remove glass, operators use a crank to create an opening that enables safe, scratch-free removal. For even greater operating convenience, faster processes, and additional storage capacity, we offer a wireless motorised variant: the KPL-F. Handling openings are triggered via wireless confirmation and, to save time, are possible directly after removal.

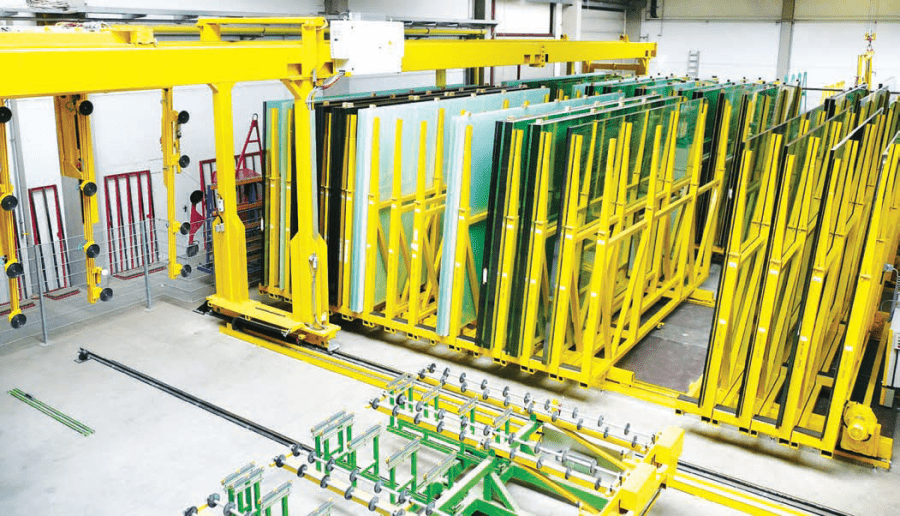

Integration of automated loading

With the KPL-A automated storage system, you attain maximum automation and integration into your processes. Fully networked and integrated into the production software, all processes are system-controlled, motorised, and precisely harmonised to the glass flow. The storage positions are located to provide quick access to loading. On the one hand, they increase the variety of products in the glass storage system and, on the other hand, they enable additional sizes to be stored.

requirements.

Easy storage management and inventory overview

If the glass storage system is supplemented by a HEGLA-HANIC storage management software or the Shop-Floor Assistant app, an accurate inventory overview is ensured at all times. You will be able to track which glass has already been reserved for production and whether or not more

panes have to be ordered or your material procurement department has already ordered them – all in real time.

Durable construction, unlimited scalability

HEGLA glass storage systems feature robust movable rack nesting, which makes them particularly lowmaintenance, torsion-resistant, and durable. Their modular construction enables you to flexibly adjust to the production requirements and glass dimensions of a production facility.

Email: carsten.koch@hegla.de

Website: www.hegla.com