South India’s Largest Glass Processing Facility Equipped With Country’s 1st Fully Automatic Pre-Processing Line

Magnum Tuff India private limited is a state-of-the-art glass processing company based in Belgaum district of Karnataka started by the Jolle Group.

Built on a 6.25-acre plot of land with one lakh square feet builtup area, Magnum Tuff is the largest glass processing facility in south India equipped with the country’s first fully automatic pre-processing line. Magnum Tuff is an allied institute of the ‘Jolle Group’. The group was started 30 years ago and today it has become a huge conglomerate with presence in seven different verticles. Jolle Group has a strong presence in the finance sector with more than 200 co-operative societies in Karnataka and Maharashtra. It also has entered the sectors of education, renewable energy, real estate, manufacturing, mining and hospitality among others.

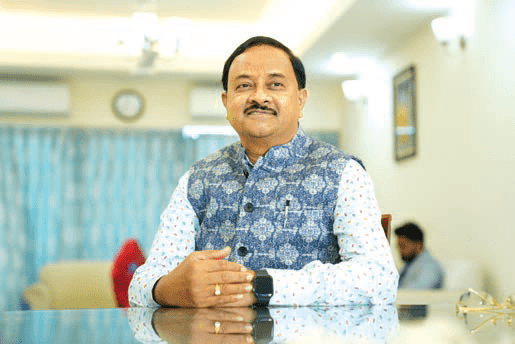

“We had started a small architectural glass processing unit in Belgaum seven years back, and saw a huge potential in this sector, and that’s why we took a huge leap by starting Magnum Tuff. This is the outcome of our commitment to serve our clients,” Jolle Group chairman Annasaheb S Jolle said about the new venture.

“I am thankful to all our clients for their support and also to my team, without their commitment and dedication we wouldn’t have achieved this milestone. I am very confident that Magnum Tuff India Pvt Ltd will make its mark in the toughened glass industry in the future,” he added. The Jolle Group team is led by Annasaheb S Jolle. Basavprasad Jolle is its managing director and Jyotiprasad Jolle is director.

Magnum Tuff aims to be the leading manufacturer of toughened glass, suitable for the architecture and the automotive industry. The company believes in maintaining a customercentric approach, providing superior quality glass products and solutions at competitive prices and meeting the needs of the customers.

It has acquired all kinds of certification, including BIS, ARAI, DOT, ISI, ISO 9001, TS 16949. The company possesses the following lab facilities – EN 12150 for toughened glass, EN 12543 for laminated safety glass, EN 1279 for insulating glass, EN 14179 for heat soaked glass, IS 2553 : PART 1 : 2018 for architectural glasses and IS 2553 : PART 2 : 2019 for automotive glasses.

-

Mr. Annasaheb S. Jolle, Chairman -

Mr. Basavprasad Jolle, MD

The company’s product range is as follows:

Architectural – tempered or toughened glass, heat strengthened glass, bent tempered glass, PVB/SGP laminated safety glass, ceramic printed glass, smart glass or private glass, insulating glass or DGU, frosting glass, bullet resistance glass, high performance glasses, curved tempered glass, curved laminated safety glass, curved insulated glass and privacy glass. Automotive – bus laminated wind shield glasses, LCV wind shield glasses, bullet resistant glasses for armored vehicles or VIP cars, sliding toughened glass, LCV side glasses (windshield, door glasses, quarter glasses, and backlights), and roof hatch glasses

Magnum Tuff boasts of an impressive array of machinery:

• CNC Glass Cutting Line with Auto Loader

• Double Edger Grinding Machine Line

• Horizontal Glass Washing Machine

• Horizontal Seaming Machine

• Ceramic Screen Printing Machine Line

• Waterjet Machine

• Flat Tempering Machine

• Insulating Glass Unit / Double Glazing Unit

• Bend Tempering Furnace

• Lamination Line with Autoclave

• Serial Bend Furnace for Automotive Glass

• Automotive Preprocessing Line

Some of the major projects Magnum Tuff has been involved in include Delta in Mangalore, KIIMS in Hubli, Tata-Hitachi plant in Dharwad, Alexandria MNG, Mangaluru International Airport, Medical College and Soliter in Anantpur, Pride Icon in Belagavi, Marvel Artiza in Hubli, SKS in Mangalore, Medical college in Bellari, Aluwind Northenskyman and the Belagavi Airport.

Website: www.magnumtuff.com